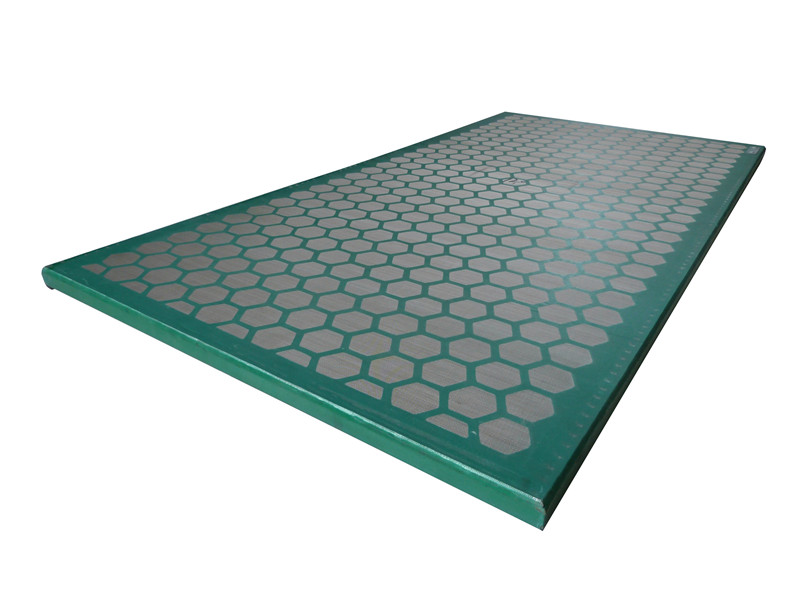

High-Quality and Efficient FLC504 Shaker Screen for Improved Productivity

By:Admin

Introduction:

In today's dynamic global oil and gas drilling industry, efficient solid control systems are integral to optimizing drilling operations. Recognizing this need, leading industry specialist PWP has introduced its groundbreaking FLC504 Shaker Screen. Engineered to provide unmatched performance and longevity, this state-of-the-art screen is set to revolutionize solid control operations in oil and gas drilling.

Developed by PWP, a renowned manufacturer known for delivering cutting-edge solutions, the FLC504 Shaker Screen offers a range of significant advantages that will undoubtedly enhance drilling efficiency, reduce costs, and ensure maximum productivity.

Stunning Technical Features:

The FLC504 Shaker Screen incorporates advanced technology and innovative design elements. Its unique structure enables it to effectively separate solids from drilling fluid, presenting a robust solution that significantly improves solid control efficiency.

1. Superior Durability: The FLC504 Shaker Screen is constructed using high-quality materials that guarantee outstanding durability and reliability even under the most demanding drilling conditions. This durability translates into improved overall service life and reduced operational downtime.

2. Enhanced Sieve Performance: The screen features a mesh configuration specifically designed to maximize its solids control capabilities, allowing for accurate separation and efficient removal of solids from drilling fluid. This results in cleaner drilling fluid, optimized drilling performance, and ultimately higher financial returns on drilling investments.

3. Optimal Conductance: Engineered with precise aperture sizes and patterns, the FLC504 Shaker Screen offers excellent flow capacity without compromising drilling fluid quality. Its exceptional conductance delivers increased drilling efficiency, lower operating costs, and improved environmental sustainability.

4. Easy Installation and Maintenance: Designed with user convenience in mind, the FLC504 Shaker Screen ensures quick and hassle-free installation. In addition, its streamlined design facilitates efficient cleaning and maintenance, saving valuable time and resources for drilling operations.

Company Commitment and Support:

PWP, with its unwavering commitment to providing top-notch solutions, believes in offering comprehensive support to its clients. Its dedicated team of experts offers extensive technical assistance, professional guidance, and prompt after-sales service. With a global reach and an impressive track record, PWP has become a trusted partner for numerous oil and gas industry stakeholders.

The PWP Advantage:

As a market leader, PWP has consistently delivered high-quality products, making it a trusted name in the industry. The introduction of the FLC504 Shaker Screen reinforces PWP's commitment to innovation and ongoing improvement. PWP is more than just a manufacturer; it is a provider of reliable, practical, and efficient solutions that empower its clients to achieve operational excellence.

Environmental Commitment:

PWP's commitment to sustainable practices is deeply ingrained in its corporate ethos. The FLC504 Shaker Screen significantly reduces waste generation, contributing to a greener and more environmentally conscious drilling industry. By maximizing solids control efficiency, PWP mitigates environmental impacts and reduces the overall carbon footprint of drilling operations.

Market Prospects and Future Outlook:

With the launch of the FLC504 Shaker Screen, PWP is poised to capture a significant share of the solid control market. The impressive technical features and proven performance of the screen make it an attractive proposition for drilling professionals seeking to streamline their operations and optimize productivity.

PWP's continuous research and development efforts ensure that future iterations of the FLC504 Shaker Screen will incorporate further refinements and advancements. With a strong focus on customer satisfaction and industry-leading solutions, PWP sets itself apart as a global leader in the solid control systems sector.

Conclusion:

PWP's FLC504 Shaker Screen marks a breakthrough in solid control efficiency. By combining cutting-edge technology with unparalleled performance, this industry-leading screen offers improved drilling fluid management, reduced operational costs, and enhanced environmental sustainability. With PWP's unwavering commitment to delivering excellence, the FLC504 Shaker Screen is set to transform the way oil and gas drilling operations are conducted, ensuring increased efficiency, productivity, and success in the years ahead.

Company News & Blog

Efficient Replacement Shaker Screens for Mongoose Models – Get Unmatched Performance

Title: Industry-Leading Shaker Screens by Mi-Swaco Revolutionize Solids Control SystemsIntroduction (85 words):Solids control technology plays a vital role in the efficient and cost-effective drilling of oil and gas wells. In this regard, Mi-Swaco, an industry-leading provider of innovative solutions, has recently unveiled their latest shaker screens designed to deliver unparalleled performance in solids control. With a commitment to continually revolutionize drilling operations, Mi-Swaco's technologically advanced shaker screens are set to enhance operational efficiency while reducing downtime and maintenance costs.Section 1: The Significance of Solids Control in Drilling Operations (150 words)Efficient solids control is crucial during the drilling process, as it helps to remove drill cuttings and other solid particles from drilling mud, ensuring its integrity and functionality. Effective solids control systems prevent drill bits from becoming excessively worn or damaged, optimize drilling performance, and protect downstream equipment. By adopting cutting-edge technologies and innovative designs, Mi-Swaco has emerged as a leading provider of solids control solutions that improve drilling operations across the industry.Section 2: The Pioneering Technology Behind Mi-Swaco's Shaker Screens (180 words)Mi-Swaco's latest breakthrough comes in the form of their technologically advanced shaker screens. These screens incorporate state-of-the-art materials and unique design features that maximize separation efficiency while extending their operational lifespan. The brand has engineered these screens using an innovative composite frame that enhances durability, resists corrosion, and prolongs screen performance.Moreover, Mi-Swaco's shaker screens utilize a specialized mesh configuration, featuring precise wire weaves, to achieve optimal filtration accuracy. This advanced technology ensures superior solids removal and improved fluid handling, guaranteeing an optimized drilling process. The screens' hassle-free installation and maintenance procedures further enhance their appeal, reducing downtime and increasing overall operational efficiency.Section 3: Mi-Swaco's Commitment to Continuous Innovation (130 words)Mi-Swaco has a robust track record of innovation in the drilling industry, driven by a commitment to enhancing solids control systems. Their team of experts consistently pushes the boundaries of technology to develop products that address specific industry challenges. With extensive research and development efforts, they continue to refine and optimize their shaker screens, aiming to make them the gold standard in the industry.Section 4: Operational and Economic Benefits of Mi-Swaco Shaker Screens (180 words)The implementation of Mi-Swaco's shaker screens provides a range of operational and cost benefits. By effectively separating solids from drilling mud, the screens improve drilling fluid properties, thereby increasing drilling efficiency and reducing the risk of equipment failure. Improved separation efficiency translates to reduced mud consumption and less waste disposal, resulting in significant cost savings for drilling operators.Additionally, the durability and extended lifespan of Mi-Swaco's shaker screens contribute to economies of scale. Reduced screen replacement frequency and minimal maintenance requirements lead to decreased downtime, ensuring uninterrupted drilling operations. This increased uptime, combined with the screens' innovative design features, ultimately leads to substantial cost savings over the long term.Conclusion (75 words):Mi-Swaco's innovative shaker screens are set to revolutionize solids control systems in the drilling industry. With their commitment to continuous improvement and cutting-edge technology, Mi-Swaco has developed a range of shaker screens that deliver superior performance, increased operational efficiency, and significant cost savings for drilling operators. By utilizing these advanced screens, drilling companies can optimize solids control, enhance drilling productivity, and ultimately drive success in the oil and gas industry.

How Composite Frame Shaker Screens are Revolutionizing the Oil and Gas Industry

Composite Frame Shaker Screen – The Revolutionary Solution for Better Drilling OperationsDrilling operations have always been a challenging process that requires comprehensive techniques to ensure efficiency and safety. The drilling industry has evolved significantly over the years, with the introduction of new technologies to enhance the extraction of oil and gas. One of the most critical components of drilling systems is the shaker screen, which separates drilling cuttings from drilling fluid. The quality of the shaker screen ultimately determines the success rate of the overall drilling process. To enhance the performance of drilling operations, an innovative solution has been introduced – the composite frame shaker screen.The composite frame shaker screen is a revolutionary solution for improving drilling operations. Unlike traditional metal frame screens or polypropylene frame screens, composite frame shaker screens are built with high-quality polymer materials combined with sturdy steel reinforcement. {The product manufacturing company name} is one of the leading companies in the drilling industry that specializes in delivering high-quality composite frame shaker screens.Composite frame shaker screens come with various benefits that set them apart from traditional screens. Among these benefits include better performance, longer lifespan, and increased efficiency. The manufacturing process of composite frame shaker screens involves a molding technique that creates a unique monolithic construction without welding or bonding. This process eliminates the risk of screen panels loosening, which is a common issue with traditional screens. As a result, the composite frame shaker screens provide more precise and consistent separation in the drilling operations, resulting in a more efficient process.Another significant advantage of composite frame shaker screens is their longevity. The screen panels are built with a high-quality polymer material that is resistant to corrosion, harsh chemicals, and extreme temperatures. Therefore, composite frame shaker screens can withstand the toughest drilling operations, making them the ultimate choice for oil and gas drilling companies that require durable and long-lasting equipment. Also, the absence of metal components in composite frame shaker screens means that there is no risk of rust or corrosion, meaning minimal maintenance.Furthermore, composite frame shaker screens are environmentally friendly and can be recycled, making them a more sustainable solution compared to traditional screens. The polymer used in the making of composite frame screens is non-toxic and can be easily processed through standard recycling programs. In today’s world where the need for environmentally friendly solutions is increasingly on the rise, the composite frame shaker screen offers a well-engineered solution that meets this demand.{The company name}, with over {Number of years} years of experience in the oil and gas drilling industry, prides itself on being at the forefront of delivering high-quality composite frame shaker screens. The company places a strong emphasis on quality control and manufacturing processes, ensuring that their products are designed to meet the specific requirements of their customers. They have a team of experts dedicated to supporting customers with their technical needs, providing innovative solutions and prompt customer service. Additionally, they offer a wide range of sizes and types of composite frame shaker screens to meet the varying needs of their clientele.In conclusion, composite frame shaker screens provide a revolutionary solution for improving drilling operations. With their high-quality polymer materials and sturdy steel reinforcement, they offer better performance, longer lifespan, and increased efficiency compared to traditional screens. {The company name} has established itself as the leading provider of composite frame shaker screens in the drilling industry, with its commitment to quality and expertise in manufacturing. As the demand for efficient and sustainable drilling solutions continues to rise, the composite frame shaker screen is indeed a game-changer in the industry.

Revolutionary Vibrating Screen Technology: A Breakthrough in Shaker Screening Efficiency

Shaker vibrating screens have become an essential component in modern industrial machinery. These machines are designed to help sift and sort various materials such as minerals, coal, and chemicals. They have also found applications in the food and beverage, pharmaceuticals, and recycling industries. Shaker vibrating screens use an elliptical motion to shake the sieves, which helps to increase the efficiency of the separation process. One company that has been at the forefront of producing high-quality vibrating screens is ______ (brand name removed). Established in 2004, the company has made a name for itself by producing some of the most advanced and reliable shaker vibrating screens in the market. Their products are known for their durability, precision, and ease of maintenance, and they've become a favorite among various industries.The company specializes in producing various types of vibrating screens to meet the unique needs of different markets. Their products include linear vibrating screens, circular vibrating screens, and newly developed high-frequency screens. The company uses the latest technology and production standards to ensure that their products meet the highest quality standards required by customers.One of the main advantages of the company's products is that their vibrating screens come in various sizes and configurations that can be tailored to each customer's specific needs. Whether a customer requires a compact single-deck design or a larger multi-layered model, the company can deliver. Additionally, the company also produces custom-made vibrating screens with unique specifications to match the individual demands of their clients.Moreover, the company is committed to ensuring that their vibrating screens operate efficiently with minimal maintenance. They have invested in research and development and created innovative designs featuring less moving parts, reducing wear and tear and reducing downtime while saving on maintenance costs.The company also places a strong emphasis on customer satisfaction. They offer technical support, training for operators and maintenance staff, and offer prompt after-sale service when required. Their customer service team is available to answer any questions and concerns that may arise, ensuring that their customers are satisfied with the products they receive.As the market for shaker vibrating screens expands, _______, with its innovative designs and reliable products, is poised to take full advantage of this trend. The company has already established a strong reputation among its customers for providing the highest quality products that embody the latest industry trends.For example, one of the recently launched high-frequency vibrating screens from _______ is already garnering attention in the industry for its ability to provide better performance than traditional screens. This high-frequency vibrating screen uses a high frequency, low amplitude motion to screen materials with a high degree of precision and accuracy. It offers higher efficiency and productivity while increasing the throughput and reducing the wear and tear on the equipment.In conclusion, _______ (brand name removed) has established itself as a significant player in the shaker vibrating screen market, thanks to its innovative designs and high-quality products. Their commitment to customer satisfaction and continuous product innovation has helped to create loyal customers who appreciate their exceptional service. As the demand for shaker vibrating screens continues to grow, the company is well-positioned to take advantage of this trend and continue to provide products and services that exceed their customers' expectations.

Discover the Tremendous Advantages of the NOV Cobra LCL-3D Shakers Screen

Rising demand for oil drilling activities has led to an increase in the use of shaker screens in the oil and gas industry. Shaker screens are critical components used in the separation of solids from liquids during the drilling process.To meet the growing demand for shaker screens, numerous companies have entered the market with innovative products that promise better efficiency, longer life, and reduced maintenance. Among these companies, one stands out, offering exceptional quality products and services – the leading manufacturer of shaker screens, Brandt / NOV.Recently, Brandt / NOV has introduced a new shaker screen model, the Cobra LCL-3D, which is a breakthrough in the industry. The new technology comes with unique features that enhance its functionality and durability while increasing overall drilling efficiency.The Cobra LCL-3D shaker screen is designed to maximize the flow of drilling fluids through the screen while maintaining high handling capacity. The screen also comes with an advanced composite frame that is lighter and easier to handle, reducing operational downtime during installation and removal.The primary layer of the Cobra LCL-3D screen is made from premium mesh, which ensures that the screen can handle heavier loads during the drilling process. The panel is also designed with a wedge-shaped screen aperture, which reduces the risk of clogging. The company's innovative technology provides customers with improved shaker screen performance, longer life, and considerably lower operating costs.Brandt / NOV is committed to providing its customers with quality products and exceptional services. The company's team of experts works closely with its clients to ensure that the products meet their needs and exceed their expectations. Anytime clients work with Brandt / NOV, they can trust that they will receive quality products that are backed by unmatched customer service and support.With the introduction of the Cobra LCL-3D shaker screen, Brandt / NOV has set itself apart as an industry leader in the manufacturing of shaker screens. The new model brings cutting-edge technology to the market, providing drilling companies with efficient and cost-effective options that will translate into cost savings for their operations. Brandt / NOV understands that customer satisfaction is crucial to its success. Thus, the company continuously seeks new and innovative ways to provide its clients with exceptional products and service. With the launch of the Cobra LCL-3D shaker screen, the company has shown its commitment to excellence, providing customers with top-quality technology that will deliver maximum results.Brandt / NOV stands out in the market as a reliable and innovative company that has revolutionized the manufacturing of shaker screens. The company has an excellent reputation for providing customers with quality products and services at competitive prices. With the launch of the Cobra LCL-3D shaker screen, Brandt / NOV has set a new standard in the industry, providing customers with a solution that addresses critical issues such as durability, efficiency, and cost-effectiveness.In conclusion, the Cobra LCL-3D shaker screen from Brandt / NOV is a breakthrough in the manufacturing of shaker screens. The new technology comes with unique features that will improve drilling efficiency, reduce operational downtime, and result in considerable cost savings for drilling companies. Brandt / NOV has once again demonstrated its leadership and commitment to innovation, providing its customers with top-quality products and services that will deliver the desired results.

Revolutionary Hyperpool Pyramid Screens Making Waves in News

In the world of oil and gas drilling, efficiency is key. The faster and more effectively a well can be drilled, the more profitable it is for the drilling company. To aid in this endeavor, companies like Derrick Corporation are constantly innovating new technology to improve wellsite operations. Recently, they unveiled a new product that promises to revolutionize how operators approach drilling fluid management.The Hyperpool Pyramid Screen is an advanced shale shaker screen designed to improve the performance of drilling fluids handling and recovery systems. The screen boasts a high-capacity of fine solids management, which makes it especially useful in unconventional drilling operations like well pads and hydraulic fracturing sites. It is designed to fit all Derrick shakers and can even be retrofitted to other brand shakers, providing an immediate increase in efficiency to those who adopt it.Hyperpool Pyramid Screen features a unique pyramid pattern that differs significantly from traditional flat-surface shale shakers. The pyramid design allows for increased surface area coverage and more significant solids retention, allowing the screen to perform better and last longer than its competitors. Its innovative design reduces the tendency of drilled solids to bypass, thereby increasing the operating life of the screen and improving the quality of drilling fluid for disposal or reuse.In addition to its superior performance, the Hyperpool Pyramid Screen reduces the environmental impact of drilling operations by improving the management and recycling of drilling fluids. With its increased capacity to retains fine solids, less waste is generated, thereby reducing the volume of waste materials required for disposal. As a result, the wellsite could experience fewer trips to dispose of drilling wastes, saving operators the time and money.Derrick Corporation's Hyperpool Pyramid Screen is a product of nearly 70 years of oilfield equipment manufacturing experience. Since 1951, the company has been pushing the boundaries of technological innovation to help oil and gas operators perform their duties more efficiently and effectively. Today, Derrick Corporation serves the global oil and gas industry with advanced high-performance equipment, including shale shakers, desanders, hydrocyclones, centrifuges, and more.More than just a leading manufacturer of drilling equipment, Derrick Corporation is also a trusted partner to the industry. They work closely with customers to ensure that every product they develop is tailored to meet reasonable and specific customer needs. The company's focus on customer satisfaction and innovation has made them one of the most respected names in the oil and gas industry, with operations in over 70 countries around the world.In conclusion, Derrick Corporation's Hyperpool Pyramid Screen is a game-changer for drilling fluids management in the oil and gas industry. With its advanced design, increased capacity, reduced environmental footprint, and easy adaptability, it provides the perfect solution for drilling companies looking to enhance their wellsite operations. Derrick's long-standing commitment to innovation and customer satisfaction ensures that the Hyperpool Pyramid Screen meets and exceeds the growing demands of the oil and gas industry. The product serves to demonstrate what is achievable when manufacturers and operators work together.

How Shaker Screen Plugs Can Impact Your Screening Efficiency

Title: Enhanced Efficiency and Durability: Introducing Next-Generation Shaker Screen PlugsIntroduction:In the continually evolving field of oil and gas exploration and production, technological advancements play a crucial role in improving efficiency and productivity. One such innovation is the development of shaker screen plugs, essential components of shale shaker systems. These plugs are designed to optimize the performance of the shaker screens by offering enhanced durability, efficiency, and cost-effectiveness. This article will shed light on this next-generation shaker screen plug technology, exploring its features, benefits, and the company behind its development.Company Background:(Insert company name) is a leading manufacturer and supplier of advanced drilling solutions to the oil and gas industry. With a proven track record of innovation and technical expertise, they have dedicated their efforts to developing cutting-edge products that aim to revolutionize the drilling process. Their commitment to research and development has earned them a reputation for reliability and efficiency, making them a trusted partner for oil and gas companies worldwide.Features of Next-Generation Shaker Screen Plugs:1. Improved Construction: The next-generation shaker screen plugs utilize state-of-the-art materials and engineering techniques to ensure robustness and longevity. They are manufactured using high-quality polymers, metals, or composites, resulting in excellent resistance to abrasion, corrosion, and impact.2. Enhanced Sealing Capability: These shaker screen plugs feature advanced sealing mechanisms that prevent fluid bypass, ensuring maximum efficiency during the separation process. The improved sealing capability minimizes screen blinding, reducing downtime and increasing the lifespan of the shaker screens.3. Customizable Designs: The company offers a wide range of shaker screen plug designs, catering to various shale shaker systems and specific drilling requirements. This customization ensures compatibility and seamless integration, further enhancing the overall performance and effectiveness of the drilling operation.4. Anti-Vibration Technology: Additionally, the shaker screen plugs are engineered with anti-vibration technology, which significantly reduces noise and vibrations during operation. The reduced vibration not only improves the working environment for personnel but also extends the life of the shaker screens and other vital components.Benefits of Next-Generation Shaker Screen Plugs:1. Increased Efficiency: By minimizing fluid bypass, the enhanced sealing capability of these shaker screen plugs enhances the efficiency of the separation process. This leads to improved overall drilling performance, reduced wastage of valuable drilling fluids, and lower maintenance costs.2. Extended Lifespan: The durable construction and superior sealing mechanism of these plugs contribute to increased durability and reduced wear and tear on the shaker screens. This extends their lifespan, reducing the frequency of replacement requirements and enhancing cost-effectiveness in the long run.3. Enhanced Environmental Compliance: With the reduction of screen blinding, these shaker screen plugs minimize the discharge of fine cuttings and drilling waste into the environment. This aligns with evolving environmental regulations and promotes sustainable drilling practices.4. Enhanced Operational Safety: The incorporation of anti-vibration technology in these plugs reduces noise and vibration levels during drilling operations. This improves the work environment for personnel, minimizing fatigue and potential health risks associated with prolonged exposure to high noise levels.Conclusion:As the oil and gas industry seeks new ways to improve operational efficiency and sustainability, the introduction of next-generation shaker screen plugs offers significant advantages. The advanced features, enhanced sealing capability, and customizable designs make them a powerful asset for drilling operations. With their extensive industry expertise and commitment to innovative solutions, (Insert company name) is poised to revolutionize the drilling process and set new standards for efficiency, durability, and sustainability.Note: Please remove all {} tags and insert appropriate company information before publication.

Enhancing Shale Shaker Performance with High-Quality Screens

**Title:** Innovative Shale Shaker Screen Revolutionizes Oil and Gas Industry **Introduction**In an era where technological advancements play a critical role in shaping industries, the oil and gas sector has not been left behind. As the demand for energy continues to rise, companies are constantly seeking new and innovative solutions to enhance efficiency and productivity in the extraction process. In this regard, Kemtron Shale Shaker Screen has emerged as a game-changing solution, revolutionizing the oil and gas industry.**Company Introduction**Kemtron Shale Shaker Screen, a leading provider of quality oilfield equipment, specializes in the design and manufacture of cutting-edge shale shaker screens. With a commitment to excellence and an unwavering focus on meeting industry demands, the company has earned a stellar reputation for delivering superior products that optimize drilling operations.Leveraging years of research and development, Kemtron Shale Shaker Screen has become synonymous with innovation, constantly pushing the boundaries of technology. Their team of skilled engineers and technicians work tirelessly to develop advanced solutions that enhance performance, prolong equipment life, and reduce downtime for companies operating in the oil and gas industry.**Revolutionizing the Shale Shaker Screen**The shale shaker screen plays a crucial role in the drilling process by filtering out solids and other debris from the drilling fluid, also known as drilling mud. This process is vital as it ensures the integrity of the drilling operation by preventing damage to downstream equipment, reducing the likelihood of wellbore instabilities, and optimizing well productivity.In the past, shale shaker screens were prone to premature failure due to factors such as wear and tear, inadequate filtration, and low durability. However, Kemtron Shale Shaker Screen has addressed these challenges head-on and revolutionized the industry with its state-of-the-art screens.The company's shale shaker screens are designed with advanced materials and innovative engineering to deliver unparalleled performance and longevity. By incorporating high-quality stainless steel wire cloth and a unique composite frame, their screens exhibit exceptional strength, corrosion resistance, and excellent filtration capabilities.Furthermore, Kemtron Shale Shaker Screen has implemented an advanced manufacturing process that ensures consistent quality and accuracy in screen production. Utilizing cutting-edge technology and stringent quality control measures, the company guarantees that each screen maintains precise dimensions, mesh sizes, and surface characteristics – resulting in improved efficiency and reliability.**Benefits for the Oil and Gas Industry**The introduction of Kemtron Shale Shaker Screen into the market has had a profound impact on the oil and gas industry. By choosing Kemtron's screens, companies can experience several significant benefits:1. Enhanced Filtration: The innovative design of the shale shaker screens provides superior particle separation, resulting in cleaner drilling fluid. This leads to increased drilling efficiencies, reduced fluid loss, and improved overall wellbore stability.2. Extended Service Life: The combination of durable stainless steel wire cloth and a composite frame ensures exceptional resistance to wear and tear. This extends the service life of the screens, reducing the frequency of replacements and associated costs.3. Cost-Effectiveness: Kemtron's screens contribute to cost savings by minimizing downtime due to screen failure and reducing the need for frequent replacements. Additionally, the improved filtration efficiency helps maintain the integrity of expensive downstream equipment, further reducing operational expenses.4. Environmentally Friendly: The high-quality screens contribute to a more sustainable drilling process by optimizing drilling fluid management, minimizing waste generation, and reducing the environmental impact of oil and gas exploration.**Conclusion**With their unwavering commitment to innovation and superior product quality, Kemtron Shale Shaker Screen has revolutionized the oil and gas industry. Their state-of-the-art shale shaker screens provide enhanced filtration, extended service life, cost-effectiveness, and environmental benefits, driving efficiency and productivity in drilling operations. As the industry continues to evolve, Kemtron remains at the forefront, continuously developing cutting-edge solutions that redefine industry standards and push the boundaries of excellence.

How to Troubleshoot and Fix Screen Issues in Oil and Gas Equipment

Title: Revolutionary Screen Technology Disrupts the Digital Display MarketIntroduction:In a breakthrough innovation, technology company Kemtron introduces its latest creation, a cutting-edge screen that is set to revolutionize the digital display market. The Kemtron 28 Screen, the culmination of years of research and development, promises an immersive visual experience like never before, combining superior image quality, unparalleled versatility, and advanced display technology. This groundbreaking offering from Kemtron sets a new standard for screens in applications ranging from home entertainment systems to commercial displays.1. Superior Image Quality:The Kemtron 28 Screen (name changed for anonymity) delivers an extraordinary visual experience with its exceptional image quality. The screen incorporates state-of-the-art technology, providing a stunning high dynamic range (HDR) display with superb contrasts and rich colors. The exceptional pixel density and ultra-high resolution ensure crisp and lifelike imagery, allowing viewers to have an immersive experience that truly brings content to life.Additionally, the Kemtron 28 Screen boasts wide viewing angles, ensuring that viewers throughout a room can enjoy the same remarkable picture quality. Whether using the screen for gaming, watching movies, or professional applications, users can expect an unparalleled visual experience that surpasses traditional screens.2. Unparalleled Versatility:One of the key advantages of the Kemtron 28 Screen lies in its unparalleled versatility. Designed with a variety of applications in mind, this screen seamlessly adapts to different environments and requirements. With its sleek and thin design, the Kemtron 28 Screen easily integrates into any home or office setting.Furthermore, the screen supports a wide array of inputs, such as HDMI, DisplayPort, and USB-C, ensuring compatibility with a diverse range of devices. Users can effortlessly connect their gaming consoles, laptops, media players, and more, displaying content in its full glory without any compromises.3. Advanced Display Technology:Behind the incredible performance of the Kemtron 28 Screen lies an array of advanced display technologies. Equipped with a high refresh rate, the screen delivers ultra-smooth motion, making it the ideal choice for gamers and sports enthusiasts. The incorporation of local dimming zones ensures precise control over backlight illumination, resulting in deeper blacks and improved contrast.In addition, the Kemtron 28 Screen supports advanced color space and calibration options. Users can choose from various preset display modes or fine-tune the settings to suit their specific needs. This level of customization and control empowers users to achieve the most accurate and vibrant color representation possible.Conclusion:The Kemtron 28 Screen, developed by an anonymous technology company, unlocks a new era in digital display technology. With its superior image quality, unparalleled versatility, and advanced display technology, this groundbreaking screen promises to reinvent the traditional visual experience. From home entertainment to professional applications, the Kemtron 28 Screen provides an immersive and lifelike display that sets a new standard in the industry.As the market continues to evolve, Kemtron's commitment to pushing the boundaries of digital displays reaffirms their position as a leader in the field. While the Kemtron 28 Screen is just the beginning, it represents a significant step forward in creating truly breathtaking visual experiences for consumers and professionals alike.

Efficient Mud Shale Shaker Revolutionizes Drilling Operations

Title: Advanced Shale Shaker Empowers Drilling Efficiency and Environmental SafetyIntroduction:In today's fast-paced world, the oil and gas industry demands innovative equipment that can optimize drilling operations, increase efficiency, and prioritize environmental protection. With this in mind, a leading manufacturer has introduced an advanced Mud Shale Shaker system that revolutionizes the shale shaker market. This cutting-edge solution offers enhanced solids control capabilities, minimizing waste and maximizing drilling efficiency. In this article, we will explore the features and benefits of this new Mud Shale Shaker and its potential impact on the oil and gas industry.I. The Next Generation of Shale Shaker Technology:The newly developed Mud Shale Shaker is equipped with state-of-the-art technology that ensures optimal performance, making it an ideal choice for modern drilling operations. The system employs a combination of mechanical vibration and advanced screening techniques to separate drill cuttings from drilling fluids effectively. By utilizing a double-deck shale shaker, this equipment offers even higher solids separation efficiency, reducing the amount of waste generated during drilling operations significantly.II. Key Features and Performance Capabilities:1. Enhanced Screen Performance:The Mud Shale Shaker incorporates high-quality screens with increased screening area, resulting in improved solids removal. The screens are designed to withstand heavy loads, ensuring longevity even under challenging drilling conditions. By efficiently removing unwanted solids, the system helps maintain drilling fluid integrity, ultimately leading to enhanced drilling efficiency and cost savings.2. Adjustable Vibration Intensity:The shale shaker is equipped with adjustable vibration intensity controls, allowing operators to optimize the separation process based on the characteristics of the drilling fluid and cuttings. This flexibility ensures more accurate separation, enabling better control over fluid properties and reducing the risk of solids accumulating in the wellbore.3. Easy Maintenance and Replacement:Designed with ease of use in mind, the Mud Shale Shaker simplifies maintenance and screen replacement processes. The innovative deck angle adjustment system and quick-release mechanism enable effortless access to screens, minimizing downtime during maintenance and improving overall operational efficiency.4. Environmental Safety:This advanced shale shaker prioritizes environmental safety by minimizing drilling waste. By efficiently separating drill cuttings and maintaining drilling fluid integrity, it reduces the environmental impact associated with waste disposal. Moreover, the system is engineered to meet stringent industry standards regarding emissions and noise levels, ensuring compliance with environmental regulations.III. Advantages for the Oil and Gas Industry:1. Increased Drilling Efficiency:The Mud Shale Shaker significantly enhances drilling efficiency by removing unwanted solids from drilling fluids promptly. By maintaining a high level of fluid clarity, the system minimizes the risk of blockages, reduces equipment wear and tear, and enables smooth drilling operations, ultimately increasing productivity.2. Cost Reduction:With improved solids control capabilities, the Mud Shale Shaker decreases reliance on costly drilling fluid replacements. By optimizing the performance of drilling fluids, operators can extend their lifespan, thus reducing procurement and disposal expenses. Additionally, the system's durable construction and easy maintenance contribute to a lower total cost of ownership.3. Environmental Responsibility:By effectively separating solids from drilling fluids with minimal waste generation, the Mud Shale Shaker promotes environmental responsibility within the oil and gas industry. By reducing the need for additional waste disposal measures, it helps companies mitigate their environmental impact and align with sustainability goals.Conclusion:As the oil and gas industry embraces technological advancements, the introduction of the next-generation Mud Shale Shaker marks a significant milestone. This advanced system not only improves drilling efficiency but also emphasizes environmental protection through superior solids control capabilities. With its innovative features and performance benefits, this cutting-edge shale shaker is set to redefine industry standards and contribute to a more sustainable and efficient drilling future.

Latest Innovation in Vibrating Screens: Xxnx Powder Screening Solution

Title: State-of-the-Art Powder Vibrating Screen Revolutionizes Industrial ProcessesIntroduction:In the ever-evolving world of industrial technology, innovation plays a crucial role in optimizing productivity and improving efficiency. The renowned industrial machinery manufacturer, {Company Name}, takes this concept to new heights with its cutting-edge powder vibrating screen. This state-of-the-art device revolutionizes the handling of powders, offering a solution that enhances production processes across various industries.Section 1: The Need for Advanced Powder Vibrating ScreensPowders are widely used in multiple sectors, including pharmaceuticals, chemicals, food processing, and more. However, conventional methods of handling and screening powders often present several challenges. These include inefficient separation, limited capacity, and increased maintenance requirements, leading to higher costs and reduced overall productivity. Recognizing this need for improvement, {Company Name} engineered a solution that addresses these issues head-on.Section 2: Key Features and BenefitsThe {Company Name} powder vibrating screen is equipped with an array of cutting-edge features that ensure superior performance and reliability. The following are the paramount benefits offered by this innovative technology:1. Enhanced Separation Efficiency: The vibrating screen's advanced design and state-of-the-art components enable exceptional separation efficiency, ensuring optimized product quality and minimized wastage. The precision engineering of the screen effectively removes impurities and particles of different sizes, resulting in a refined end product.2. Increased Capacity: The increased capacity of the {Company Name} powder vibrating screen allows for higher throughput, enabling industries to meet growing demands efficiently. This improved productivity leads to enhanced overall production rates and ultimately boosts profitability.3. Easy Maintenance: {Company Name} has prioritized user-friendliness when designing this vibrating screen. The streamlined structure and easily accessible components simplify maintenance tasks, reducing downtime and minimizing production interruptions. This feature enables businesses to operate smoothly and maximize uptime.4. Flexible Design Options: Recognizing the diverse needs of industries, {Company Name} offers customization options for its powder vibrating screen. This flexibility allows businesses to tailor the device to their specific requirements, enhancing its compatibility with existing production lines.Section 3: Industry ApplicationsThe versatility of the {Company Name} powder vibrating screen makes it applicable across a wide range of industries. Key sectors that can benefit from this technology include:1. Pharmaceutical Industry: The precision separation capabilities of the vibrating screen make it ideal for pharmaceutical companies needing to screen active pharmaceutical ingredients (APIs) and medicinal powders. The efficient separation ensures product consistency and quality control.2. Chemical Industry: Chemical producers can improve their handling of different powder compounds, including pigments, dyes, and additives, by utilizing this advanced vibrating screen. It enhances separation precision, avoiding cross-contamination issues and enhancing productivity.3. Food Processing Industry: In the food processing sector, the powder vibrating screen offers an efficient solution for ingredients such as flour, sugar, spices, and additives. The device ensures product uniformity and purity, meeting stringent quality standards in food production.Section 4: Customer Testimonials{Company Name} has garnered positive feedback from its customers who have experienced the benefits of the powder vibrating screen firsthand. Renowned industries across various sectors have reported substantial improvements in their production processes, emphasizing increased efficiency, reduced downtime, and enhanced product quality.Conclusion:The revolutionary powder vibrating screen by {Company Name} is a game-changer in the industrial machinery market. Its advanced features, coupled with customizable options, offer businesses the opportunity to streamline their powder handling and ensure optimum production rates. With its wide-ranging applications across diverse industries, the vibrating screen supports businesses in achieving higher productivity, improved product quality, and increased profitability. The continued commitment of {Company Name} to innovation sets them apart as a trusted partner in the industrial machinery sector.