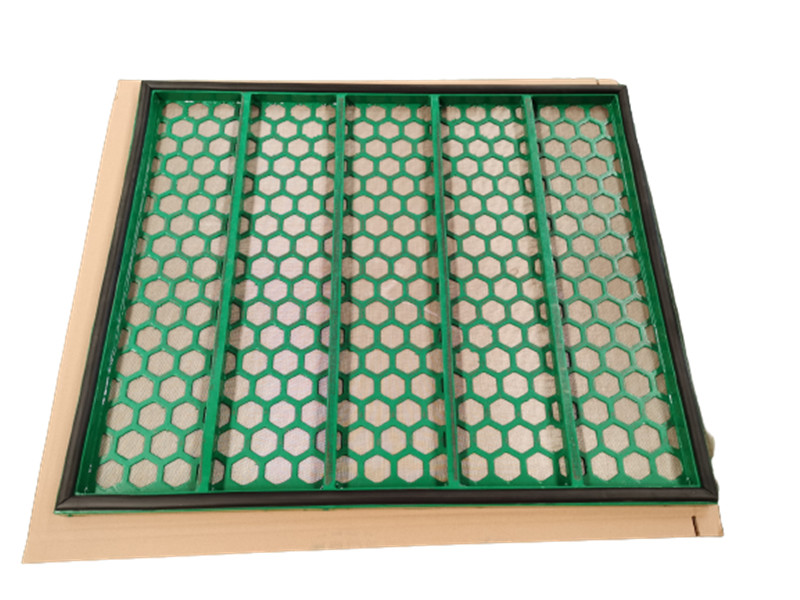

High-quality Shaker Screen for Oil and Gas Industry Applications

By:Admin

The HYP PWP Shaker Screen is the result of years of research and development, aimed at addressing the challenges faced in shale shaker operations. This new generation of shaker screens offers a significant improvement in performance, with enhanced solids removal and increased fluid handling capacity. The innovative design of the HYP PWP Shaker Screen ensures a longer lifespan and reduced maintenance, resulting in cost savings for oil and gas operators.

Derrick Corporation has long been recognized for its commitment to advancing separation technology, and the introduction of the HYP PWP Shaker Screen further solidifies its position as a leader in the industry. The company's dedication to quality and innovation is evident in the design and engineering of this new product, which is set to revolutionize shale shaker performance.

With a global footprint and a strong presence in major oil and gas producing regions, Derrick Corporation is well-positioned to meet the growing demands of the industry. The company's extensive experience and expertise in solids control equipment make it a trusted partner for oilfield operators seeking reliable and efficient solutions. The HYP PWP Shaker Screen is yet another example of Derrick Corporation's commitment to delivering superior products that meet the evolving needs of the oil and gas sector.

In addition to its innovative products, Derrick Corporation also offers comprehensive aftermarket support and service to ensure the optimal performance of its equipment. The company's team of experts provides technical assistance, training, and maintenance services to help customers maximize the value of their investment in Derrick products. This commitment to customer satisfaction further underscores Derrick Corporation's reputation as a reliable and trusted partner in the oil and gas industry.

The launch of the HYP PWP Shaker Screen marks a significant milestone for Derrick Corporation, as it continues to lead the way in advancing separation technology for the oil and gas sector. This new product is set to deliver tangible benefits for oilfield operators, including improved efficiency, reduced maintenance costs, and enhanced drilling fluid performance. With its proven track record of innovation and excellence, Derrick Corporation is well-positioned to shape the future of solids control equipment and make a lasting impact on the oil and gas industry.

Company News & Blog

High-Quality Shaker Screen for Efficient Separation of Solids and Liquids

Title: Innovative Shale Shaker Screen Revolutionizes Drilling IndustryIntroduction:In an era of technological advancements, the drilling industry constantly seeks innovative solutions to improve efficiency and reduce costs. As drilling operations become increasingly complex, ensuring reliable and efficient separation of solids from drilling fluid is crucial. Enter an industry-leading product that is making waves with its exceptional performance - the Venom Shaker Screen.Revolutionizing the way drilling companies approach solid control, the Venom Shaker Screen, developed by an innovative company, offers a cutting-edge solution that not only enhances efficiency but also reduces downtime and operational costs. This advanced shale shaker screen is poised to transform the drilling industry by leveraging its unique features and superior performance.Unveiling Advancements:The Venom Shaker Screen is designed to eliminate the common limitations of conventional shaker screens. Its groundbreaking technology effectively removes solids, ensuring better drilling fluid quality without compromising capacity. Developed using a combination of premium materials and advanced manufacturing techniques, this product offers unparalleled durability, reliable performance, and increased efficiency.Key Features:1. Enhanced Solid Control: The Venom Shaker Screen utilizes a state-of-the-art design that promotes efficient solid separation. The combination of precise mesh sizes and reinforced frame construction ensures optimal particle retention while efficiently allowing drilling fluid to pass through.2. Maximum Cuttings Recovery: With its unique layered design, the Venom Shaker Screen maximizes the recovery of valuable drill cuttings, promoting efficient disposal and reducing waste. This results in cost savings for drilling companies.3. Durable Construction: The screen is built to withstand the harsh conditions encountered during drilling operations. With a rugged frame and corrosion-resistant materials, it offers longevity and reduced maintenance requirements, minimizing downtime and associated costs.4. Versatile Application: The Venom Shaker Screen is compatible with various shale shakers, allowing drilling companies to seamlessly integrate it into their existing operations. Its universal design ensures easy installation and replacement, eliminating the need for costly equipment modifications.Industry Impact:The introduction of the Venom Shaker Screen marks a significant milestone in the drilling industry. By improving the efficiency of solid control and reducing waste, this innovative product enhances drilling operations on multiple levels:1. Increased Efficiency: The Venom Shaker Screen's superior solid separation capabilities result in improved drilling fluid quality, allowing for more efficient and effective drilling operations. This translates into reduced drilling time and increased productivity.2. Cost Reduction: The screen's ability to maximize cuttings recovery results in reduced waste disposal costs. Additionally, its durability minimizes maintenance and replacement expenses, optimizing overall operational costs for drilling companies.3. Environmental Benefits: By minimizing waste and promoting efficient disposal of drill cuttings, the Venom Shaker Screen contributes to environmentally responsible drilling practices. This advancement aligns with the industry's growing focus on sustainable operations.Partnerships and Future Developments:The development and success of the Venom Shaker Screen are a testament to the company's commitment to innovation. Collaborations with drilling companies worldwide have allowed for real-time feedback, resulting in continuous improvements.Furthermore, ongoing research and development efforts aim to enhance the screen's capabilities even further. These future developments will provide drilling companies with an even more efficient and reliable solution, ensuring continuous progress in the industry.Conclusion:The introduction of the Venom Shaker Screen signifies a game-changing advancement in the drilling industry. By addressing the limitations of traditional shaker screens and offering exceptional solid control capabilities, this innovative product has the potential to revolutionize drilling operations.With its enhanced efficiency, cost-saving features, and commitment to sustainability, the Venom Shaker Screen is poised to become an essential component in the arsenal of drilling companies worldwide. Embracing this groundbreaking technology will enable drilling operations to thrive in an increasingly competitive and dynamic industry.

Top-notch Shaker Screens for King Cobra Now Available - Latest News and Updates

Title: Cutting-Edge Shaker Screen Takes the Oil and Gas Industry by StormIntroduction[Company Name], a leading player in the oil and gas industry, has unveiled its latest innovation, the NOV Brandt King Cobra Shaker Screen. Designed to revolutionize the solids control and waste management process, this cutting-edge shaker screen promises to streamline drilling operations and enhance efficiency. By removing drilling solids and efficiently separating them from drilling fluid, this state-of-the-art technology aims to optimize the performance and lifespan of equipment, ultimately reducing costs and improving environmental sustainability. Let us delve deeper into the features and benefits of this remarkable product.Advanced Technology and Robust DesignThe NOV Brandt King Cobra Shaker Screen integrates advanced technology to deliver unparalleled performance in solids control. Incorporating a high-density technology mesh with a multi-layered design, this shaker screen ensures superior filtration capabilities, effectively removing unwanted particles and achieving particle size separation. The robust design ensures durability, enabling this screen to withstand the most demanding drilling conditions without compromising performance.Enhanced Efficiency and Cost ReductionEmploying the NOV Brandt King Cobra Shaker Screen in drilling operations brings forth several advantages that translate into enhanced efficiency and cost reduction. By effectively removing drilling solids, this screen prevents equipment from becoming clogged and greatly improves overall drilling fluid quality. The improved drilling fluid properties allow for increased drilling penetration rates, reducing downtime and boosting productivity. Additionally, with the elimination of unwanted solids in the drilling fluid, equipment lifespan is extended, leading to reduced maintenance costs and equipment replacement.By optimizing solids control, the NOV Brandt King Cobra Shaker Screen enables oil and gas companies to significantly minimize waste generation. The separation of drilling solids from the drilling fluid ensures that the recycled fluid can be reused efficiently, thereby reducing the need for freshly prepared drilling fluid. This not only cuts down on drilling fluid expenses but also contributes to environmental sustainability by lowering waste disposal requirements.Quality Control and ComplianceAs a trusted provider in the industry, [Company Name] ensures that the NOV Brandt King Cobra Shaker Screen adheres to the strictest quality control standards. The screen is designed to withstand rigorous testing and meets all industry specifications. Rigorous quality control measures are implemented throughout the manufacturing process to guarantee consistent performance and reliability.The NOV Brandt King Cobra Shaker Screen also complies with environmental regulations related to waste management in the oil and gas sector. By implementing this technology, companies can demonstrate their commitment to sustainable practices, preserving natural resources, and minimizing their ecological footprint.Global Reach and Market ImpactWith its innovative design and unmatched performance, the NOV Brandt King Cobra Shaker Screen has garnered significant attention and interest from oil and gas companies globally. [Company Name] has positioned itself as a global leader in providing efficient solids control solutions, empowering drilling operations worldwide. The company's dedication to innovation, customer-centric approach, and commitment to quality has propelled its products into the spotlight, securing its position as an industry frontrunner.ConclusionThe introduction of the NOV Brandt King Cobra Shaker Screen by [Company Name] signifies a breakthrough solution in solids control and waste management in the oil and gas industry. Its cutting-edge technology, robust design, and impressive performance set new standards for efficiency and cost reduction. By effectively removing drilling solids and optimizing drilling fluid quality, this shaker screen enhances overall equipment lifespan, productivity, and environmental sustainability. As the industry faces mounting challenges, [Company Name] continues to innovate and develop solutions that redefine the future of oil and gas operations.

Discover the Latest Innovation in Shale Shaker Screen Technology with the Kemtron 28 Series

Title: Groundbreaking Kemtron 28 Series Shale Shaker Screens Revolutionize the Oil and Gas IndustryIntroduction:In the ever-evolving world of oil and gas exploration, the demand for reliable and efficient shale shaker screens has never been higher. Addressing this need, a leading industry player introduces their latest innovation - the Kemtron 28 Series Shale Shaker Screens. Designed to deliver exceptional performance, these screens are set to revolutionize the oil and gas industry, offering enhanced productivity and cost-efficiency. Let us delve deeper into the remarkable features that make the Kemtron 28 Series a game-changer.Unparalleled Quality and Durability:One of the most remarkable aspects of the Kemtron 28 Series Shale Shaker Screens is their superior build quality and exceptional durability. Constructed using advanced materials and cutting-edge manufacturing techniques, these screens offer a level of resilience and longevity that surpasses industry standards. Their innovative design ensures resistance to wear, abrasion, and corrosion, thereby minimizing replacement frequency and reducing maintenance costs for oil and gas companies.Optimized Performance:The Kemtron 28 Series Shale Shaker Screens are engineered to deliver exceptional performance by maximizing solids control efficiency. Their precise mesh sizes and configuration enable the screens to efficiently separate and remove solid particles from drilling fluids, ensuring the production of cleaner and higher-quality fluid. This not only enhances the drilling process but also minimizes the risk of equipment failures, ultimately leading to improved operational efficiency and reduced downtime.Enhanced Operational Efficiency:The incorporation of the Kemtron 28 Series Shale Shaker Screens into an oil and gas operation brings with it a multitude of benefits that lead to enhanced operational efficiency. The screens' exceptional solids control efficiency reduces the volume of drilling fluid required, resulting in significant cost savings. Furthermore, by maintaining optimal fluid viscosity, the screens contribute to improved drilling speed and accuracy, ultimately reducing overall project timelines. These combined factors propel the oil and gas industry towards faster, more efficient operations.Eco-Friendly Solution:Sustainability is a key consideration in the modern oil and gas industry, and the Kemtron 28 Series Shale Shaker Screens deliver in this area as well. By effectively separating solids from drilling fluids, these screens minimize the environmental impact of drilling activities. Clean drilling fluids can be effectively recycled, reducing the volume of waste generated and mitigating the potential harm to ecosystems. The adoption of the Kemtron 28 Series screens not only enhances operational efficiency but also demonstrates a commitment to responsible environmental practices.Unparalleled Support and Service:Recognizing the importance of seamless customer support, the company behind the Kemtron 28 Series Shale Shaker Screens prides itself on its dedicated after-sales service. With a global network of technical experts and service centers, customers can rest assured that their queries and concerns will be promptly addressed. This comprehensive support ensures that the screens continue to operate at their best, maximizing their potential and delivering exceptional value to oil and gas companies around the world.Conclusion:The introduction of the Kemtron 28 Series Shale Shaker Screens has caused ripples of excitement throughout the oil and gas industry. Boasting unparalleled quality, optimized performance, enhanced operational efficiency, and a commitment to sustainability, these screens have quickly become the go-to choice for industry professionals. As oil and gas companies strive for greater productivity while prioritizing environmental responsibility, the Kemtron 28 Series Shale Shaker Screens emerge as a groundbreaking solution that will shape the future of the industry.

Analyzing the Latest Advancements in Atl 1000 Shaker Screen Technology

In the world of drilling and oil production, the utilization of efficient and high-quality equipment has been a major factor in ensuring the success of operations. Among these pieces of equipment is the shaker screen, which plays a vital role in optimizing the drilling process. A shaker screen is essentially a sieve, which separates the drilling fluids from the solids, thereby decreasing the waste generation and allowing the recyclability of drilling mud. As such, the quality and performance of shaker screens are of utmost importance to companies in the oil and gas industry.One of the top-rated shaker screens in the industry is the Brandt Atl 1000 (brand name removed) shaker screen. This shaker screen boasts of a variety of features that make it stand out from the rest. Its technology and design are based on the latest advancements in the industry, optimizing its performance to meet the demands of drilling operations.The Brandt Atl 1000 shaker screen has been engineered to enhance the separation process of drilling fluids and solids. The screen has a large effective screen area, which translates to a better-solid removal efficiency. In addition, the screen is designed to prevent the clogging of particles, thereby increasing its overall performance.Another feature that makes the Brandt Atl 1000 shaker screen popular among drilling companies is its durability. The screen has been constructed from high-quality materials that ensure it can withstand the harsh conditions that exist in the oil and gas industry. Furthermore, the mesh layers of the screen have been treated with a specialized chemical that protects them from wear and tear, increasing its lifespan.The design of the screen has also been tailored to provide ease of use for the operator. The screen uses a hook-strip feature, which enables its installation or removal to be done in a shorter time period. This feature is crucial as it significantly reduces the downtime, which would have a negative effect on the overall operation.Moreover, the Brandt Atl 1000 shaker screen has a unique labeling system that allows for optimal identification and tracking of the screen’s maintenance and repair history. This feature is important as it ensures that the screen is well-maintained, guaranteeing optimal performance during its lifespan.The Brandt Atl 1000 shaker screen has been embraced by drilling companies worldwide, with positive feedback being received on its performance and durability. In addition, it has been tested and validated to meet the industry standards, with a false-positive rate of less than 5%. This low rate of false positives is essential in ensuring that drilling companies can accurately identify and separate solids from drilling mud.Therefore, the Brandt Atl 1000 shaker screen has become a go-to for drilling companies worldwide, with its high-quality performance, durability, and ease of use being among the top reasons for this. The screen’s design and technology have been optimized to meet the needs of the industry, ensuring that drilling companies can operate efficiently, with minimal waste generation, and maximum yield. While the market for shaker screens is competitive, the Brandt Atl 1000 shaker screen has managed to stand out, with its features enabling it to meet and exceed the expectations of the oil and gas industry.

How Composite Frame Shaker Screens are Revolutionizing the Oil and Gas Industry

Composite Frame Shaker Screen – The Revolutionary Solution for Better Drilling OperationsDrilling operations have always been a challenging process that requires comprehensive techniques to ensure efficiency and safety. The drilling industry has evolved significantly over the years, with the introduction of new technologies to enhance the extraction of oil and gas. One of the most critical components of drilling systems is the shaker screen, which separates drilling cuttings from drilling fluid. The quality of the shaker screen ultimately determines the success rate of the overall drilling process. To enhance the performance of drilling operations, an innovative solution has been introduced – the composite frame shaker screen.The composite frame shaker screen is a revolutionary solution for improving drilling operations. Unlike traditional metal frame screens or polypropylene frame screens, composite frame shaker screens are built with high-quality polymer materials combined with sturdy steel reinforcement. {The product manufacturing company name} is one of the leading companies in the drilling industry that specializes in delivering high-quality composite frame shaker screens.Composite frame shaker screens come with various benefits that set them apart from traditional screens. Among these benefits include better performance, longer lifespan, and increased efficiency. The manufacturing process of composite frame shaker screens involves a molding technique that creates a unique monolithic construction without welding or bonding. This process eliminates the risk of screen panels loosening, which is a common issue with traditional screens. As a result, the composite frame shaker screens provide more precise and consistent separation in the drilling operations, resulting in a more efficient process.Another significant advantage of composite frame shaker screens is their longevity. The screen panels are built with a high-quality polymer material that is resistant to corrosion, harsh chemicals, and extreme temperatures. Therefore, composite frame shaker screens can withstand the toughest drilling operations, making them the ultimate choice for oil and gas drilling companies that require durable and long-lasting equipment. Also, the absence of metal components in composite frame shaker screens means that there is no risk of rust or corrosion, meaning minimal maintenance.Furthermore, composite frame shaker screens are environmentally friendly and can be recycled, making them a more sustainable solution compared to traditional screens. The polymer used in the making of composite frame screens is non-toxic and can be easily processed through standard recycling programs. In today’s world where the need for environmentally friendly solutions is increasingly on the rise, the composite frame shaker screen offers a well-engineered solution that meets this demand.{The company name}, with over {Number of years} years of experience in the oil and gas drilling industry, prides itself on being at the forefront of delivering high-quality composite frame shaker screens. The company places a strong emphasis on quality control and manufacturing processes, ensuring that their products are designed to meet the specific requirements of their customers. They have a team of experts dedicated to supporting customers with their technical needs, providing innovative solutions and prompt customer service. Additionally, they offer a wide range of sizes and types of composite frame shaker screens to meet the varying needs of their clientele.In conclusion, composite frame shaker screens provide a revolutionary solution for improving drilling operations. With their high-quality polymer materials and sturdy steel reinforcement, they offer better performance, longer lifespan, and increased efficiency compared to traditional screens. {The company name} has established itself as the leading provider of composite frame shaker screens in the drilling industry, with its commitment to quality and expertise in manufacturing. As the demand for efficient and sustainable drilling solutions continues to rise, the composite frame shaker screen is indeed a game-changer in the industry.

Durable Steel Frame Screen for Swaco Mamut Shakers" - Removed Brand Name

Swaco Mamut Steel Frame Screen (SWM) continues to demonstrate its commitment to innovation and excellence in the oil and gas industry, as it further establishes itself as a top provider of high-quality, durable, and efficient screens for the sector. SWM's steel frame screens have been praised for their reliability and performance, making them a top choice for companies looking to optimize their operations.A key factor that sets SWM apart from its competitors is its dedication to research and development. The company invests heavily in this area, constantly seeking new ways to improve its products and stay ahead of the curve in the industry. SWM also places a strong emphasis on customer feedback, using it to drive product improvements and ensure that its screens continue to meet the evolving demands of its clients.SWM's steel frame screens are designed to withstand the harshest conditions found in oil and gas operations. These screens are built to last, with a focus on durability and performance. This is critical in an industry where equipment needs to be able to endure extreme temperatures, high pressure, and corrosive materials. SWM's screens have been rigorously tested and proven to meet these demanding requirements.One of the key advantages of SWM's steel frame screens is their versatility. They can be used in a wide range of applications, from primary shale shakers to mud cleaners and desanders. This flexibility makes them a valuable asset for companies looking to streamline their operations and reduce downtime. The ability to use the same high-quality screens across multiple processes helps companies save time and money while maintaining a high level of efficiency.In addition to their durability and versatility, SWM's steel frame screens are also known for their exceptional performance. They are designed to provide effective solid-liquid separation, ensuring that drilling operations can run smoothly and efficiently. This is crucial for maximizing productivity and minimizing waste in the extraction process. SWM's screens have a proven track record of delivering these critical benefits, further solidifying their status as a top choice for oil and gas companies.SWM's commitment to excellence extends beyond its products to its customer service. The company has a team of dedicated professionals who are ready to provide support and assistance to clients, ensuring that they get the most out of their screens. Whether it's troubleshooting, maintenance, or general advice, SWM's experts are there to help every step of the way. This level of support is yet another reason why SWM has earned a reputation as a trusted and reliable partner in the industry.Looking to the future, SWM remains dedicated to pushing the boundaries of what is possible in the oil and gas sector. The company's ongoing investment in research and development will continue to drive innovation and lead to the introduction of new and improved products. SWM is committed to staying at the forefront of the industry, providing its clients with the tools they need to succeed in an ever-changing and demanding market.In conclusion, SWM's steel frame screens have firmly established themselves as a top choice for oil and gas companies seeking reliable, durable, and high-performance equipment. With a focus on innovation, quality, and customer service, SWM has proven itself to be a valuable partner in the industry. As the company continues to invest in its products and support services, it is well-positioned to remain a leader in the sector for years to come.

High Quality 48 PMD Shaker Screen for Derrick Model

Derrick Corporation, a global leader in manufacturing high-performance separation and filtration equipment, has recently introduced the Derrick 48 PMD Shaker Screen, the latest addition to their extensive product line. This new shaker screen is designed to provide superior performance and longevity, meeting the growing demands of the oil and gas industry.The Derrick 48 PMD Shaker Screen is engineered with advanced technology and exceptional quality materials to ensure efficient and effective solids control. It features a unique pyramid design that increases the usable screen area, providing better capacity and longer screen life. This innovative design allows for increased fluid handling capacity and improved solids removal, ultimately leading to higher productivity and cost savings for the operators.With a focus on durability and reliability, the Derrick 48 PMD Shaker Screen is built to withstand the harsh operating conditions of drilling operations. Its robust construction and precise manufacturing process ensure consistent and reliable performance, even in the most challenging environments. This makes it an ideal choice for operators looking to optimize their solids control processes and reduce overall operating costs.In addition to its exceptional performance, the Derrick 48 PMD Shaker Screen is designed for easy installation and maintenance. Its user-friendly design allows for quick and simple screen replacement, minimizing downtime and maximizing operational efficiency. This feature is particularly beneficial for operators looking to streamline their maintenance procedures and enhance overall equipment uptime.Moreover, the Derrick 48 PMD Shaker Screen is compatible with a wide range of shale shakers, making it a versatile solution for various drilling applications. Its adaptability and flexibility make it an attractive option for operators seeking a reliable and cost-effective solids control solution that can be easily integrated into their existing equipment fleet.Derrick Corporation, with over 70 years of experience in the industry, has built a solid reputation for delivering innovative and high-quality separation and filtration solutions. The introduction of the Derrick 48 PMD Shaker Screen further solidifies their commitment to providing cutting-edge technologies that address the evolving needs of the oil and gas industry.The company’s dedication to research and development, coupled with their extensive industry expertise, has positioned Derrick Corporation as a trusted partner for operators seeking best-in-class solids control and filtration solutions. Their relentless pursuit of excellence and customer-centric approach have made them a preferred choice for companies looking to optimize their drilling operations and maximize performance.In conclusion, the Derrick 48 PMD Shaker Screen represents a significant advancement in solids control technology, offering unmatched performance, durability, and versatility. Backed by Derrick Corporation’s unparalleled reputation and commitment to innovation, this new shaker screen is set to redefine industry standards and empower operators to achieve greater efficiency and productivity in their operations. As the oil and gas industry continues to evolve, Derrick Corporation remains at the forefront, providing cutting-edge solutions that address the dynamic challenges of the industry.

New Primary Oil Shaker Screen with Multi-sizing Technology Announced in Recent News

New Multi-sizer Primary Oil Shaker Screen Revolutionizes Oil and Gas IndustryThe oil and gas industry, which plays a crucial role in powering the global economy, constantly seeks innovative technologies to enhance drilling operations and improve overall efficiency. In line with this ongoing pursuit, a cutting-edge product has emerged that promises to revolutionize the industry - the Multi-sizer Primary Oil Shaker Screen.Developed by a renowned industry leader, the Multi-sizer Primary Oil Shaker Screen is set to redefine the way oil and gas companies approach their drilling procedures. With its unprecedented technological advancements and impressive features, this new product positions itself as a game-changer in the field.The Multi-sizer Primary Oil Shaker Screen replaces the traditional approach to shale shaker screens, offering a level of efficiency and performance never seen before. Its key advantage lies in its ability to screen drilling fluids more effectively, leading to improved solids separation and increased productivity. This vital feature significantly reduces overall operational costs and downtime, allowing companies to optimize their drilling operations for maximum output.One of the standout features of the Multi-sizer Primary Oil Shaker Screen is its versatility. Unlike conventional screens, this innovative product can be adjusted to accommodate various drilling conditions and formations. From fine to coarse meshes, the Multi-sizer Primary Oil Shaker Screen is engineered to handle a wide range of drilling fluid sizes, ensuring optimal filtration in every scenario.Moreover, the new screen boasts an impressive retention rate, effectively capturing and retaining drilled solids during the filtration process. This not only minimizes the risk of contaminants in the drilling fluid but also extends the lifespan of the screen itself. With longer-lasting screens, oil and gas companies can further reduce operational costs and enhance their environmental stewardship by minimizing waste and resource consumption.Additionally, the Multi-sizer Primary Oil Shaker Screen is built with durability in mind. Constructed using high-quality materials and employing rigorous manufacturing processes, this product offers exceptional longevity even in the harshest drilling conditions. With its resistance to wear and tear, companies can rely on the Multi-sizer Primary Oil Shaker Screen to withstand the demanding nature of oil and gas operations, reducing the need for frequent replacements and maintenance.Furthermore, the Multi-sizer Primary Oil Shaker Screen simplifies the maintenance process itself. Its user-friendly design allows for quick and easy installation, minimizing downtime during screen replacements. This streamlined approach ensures that drilling operations can resume promptly, maximizing efficiency and minimizing disruptions.Despite its numerous advantages, the Multi-sizer Primary Oil Shaker Screen remains incredibly cost-effective. By improving solids control and extending screen lifespan, companies can achieve substantial savings in operational costs. The enhanced productivity and reduced downtime offered by this innovative product will undoubtedly translate into significant financial gains for oil and gas companies.The introduction of the Multi-sizer Primary Oil Shaker Screen marks a turning point in the oil and gas industry. Its groundbreaking features and exceptional performance are set to transform drilling operations, enabling companies to enhance productivity, reduce costs, and improve environmental sustainability. By embracing this cutting-edge technology, oil and gas companies can stay ahead of the curve and propel the industry into a more efficient and prosperous future.In conclusion, the Multi-sizer Primary Oil Shaker Screen represents a breakthrough innovation in the oil and gas industry. With its advanced features, versatility, durability, and cost-effectiveness, this revolutionary product is poised to redefine how drilling operations are conducted worldwide. As oil and gas companies strive for greater efficiency and sustainability, the Multi-sizer Primary Oil Shaker Screen emerges as an indispensable tool in their path towards success.

Efficient Mud Shale Shaker Revolutionizes Drilling Operations

Title: Advanced Shale Shaker Empowers Drilling Efficiency and Environmental SafetyIntroduction:In today's fast-paced world, the oil and gas industry demands innovative equipment that can optimize drilling operations, increase efficiency, and prioritize environmental protection. With this in mind, a leading manufacturer has introduced an advanced Mud Shale Shaker system that revolutionizes the shale shaker market. This cutting-edge solution offers enhanced solids control capabilities, minimizing waste and maximizing drilling efficiency. In this article, we will explore the features and benefits of this new Mud Shale Shaker and its potential impact on the oil and gas industry.I. The Next Generation of Shale Shaker Technology:The newly developed Mud Shale Shaker is equipped with state-of-the-art technology that ensures optimal performance, making it an ideal choice for modern drilling operations. The system employs a combination of mechanical vibration and advanced screening techniques to separate drill cuttings from drilling fluids effectively. By utilizing a double-deck shale shaker, this equipment offers even higher solids separation efficiency, reducing the amount of waste generated during drilling operations significantly.II. Key Features and Performance Capabilities:1. Enhanced Screen Performance:The Mud Shale Shaker incorporates high-quality screens with increased screening area, resulting in improved solids removal. The screens are designed to withstand heavy loads, ensuring longevity even under challenging drilling conditions. By efficiently removing unwanted solids, the system helps maintain drilling fluid integrity, ultimately leading to enhanced drilling efficiency and cost savings.2. Adjustable Vibration Intensity:The shale shaker is equipped with adjustable vibration intensity controls, allowing operators to optimize the separation process based on the characteristics of the drilling fluid and cuttings. This flexibility ensures more accurate separation, enabling better control over fluid properties and reducing the risk of solids accumulating in the wellbore.3. Easy Maintenance and Replacement:Designed with ease of use in mind, the Mud Shale Shaker simplifies maintenance and screen replacement processes. The innovative deck angle adjustment system and quick-release mechanism enable effortless access to screens, minimizing downtime during maintenance and improving overall operational efficiency.4. Environmental Safety:This advanced shale shaker prioritizes environmental safety by minimizing drilling waste. By efficiently separating drill cuttings and maintaining drilling fluid integrity, it reduces the environmental impact associated with waste disposal. Moreover, the system is engineered to meet stringent industry standards regarding emissions and noise levels, ensuring compliance with environmental regulations.III. Advantages for the Oil and Gas Industry:1. Increased Drilling Efficiency:The Mud Shale Shaker significantly enhances drilling efficiency by removing unwanted solids from drilling fluids promptly. By maintaining a high level of fluid clarity, the system minimizes the risk of blockages, reduces equipment wear and tear, and enables smooth drilling operations, ultimately increasing productivity.2. Cost Reduction:With improved solids control capabilities, the Mud Shale Shaker decreases reliance on costly drilling fluid replacements. By optimizing the performance of drilling fluids, operators can extend their lifespan, thus reducing procurement and disposal expenses. Additionally, the system's durable construction and easy maintenance contribute to a lower total cost of ownership.3. Environmental Responsibility:By effectively separating solids from drilling fluids with minimal waste generation, the Mud Shale Shaker promotes environmental responsibility within the oil and gas industry. By reducing the need for additional waste disposal measures, it helps companies mitigate their environmental impact and align with sustainability goals.Conclusion:As the oil and gas industry embraces technological advancements, the introduction of the next-generation Mud Shale Shaker marks a significant milestone. This advanced system not only improves drilling efficiency but also emphasizes environmental protection through superior solids control capabilities. With its innovative features and performance benefits, this cutting-edge shale shaker is set to redefine industry standards and contribute to a more sustainable and efficient drilling future.

Latest Innovations in 48-inch Screens: Discover the Game-Changing Kemtron Technology

In a world full of technology, it is hard not to appreciate some of the best tech gadgets such as smart TVs, smartphones, and laptops. Screens have become an integral part of our everyday lives. Be it for work purposes, entertainment, or education, people are constantly in need of high-quality screens with excellent display features. In this regard, the kemtron 48-inch screen stands out as one of the best screens to have for all your visual needs.The kemtron 48-inch screen is an excellent investment for anyone who wants to enjoy the best viewing experience. The screen features high resolution, excellent picture quality, and a range of features that make it ideal for use in various environments. Whether you need a screen for home entertainment or your company’s boardroom meetings, the kemtron 48-inch screen is capable of meeting all your needs.The kemtron screen 48-inch screen boasts of a high-resolution display, capable of producing crystal-clear images. With a resolution of 1080p, you can view high-definition content with stunning details. This screen size is perfect for home entertainment, corporate boardrooms, classrooms, movie theaters, and other large venues that require clear and high-quality visuals.Additionally, the kemtron 48-inch screen comes with an LCD display technology that maximizes color accuracy, contrast, and brightness. The result is a screen that produces vivid and lifelike images that are true to life. With a clear and bright screen, you can enjoy your favorite movies, TV shows, games, or professional presentations and conferences without straining your eyes.The kemtron 48-inch screen also comes with several features that make it ideal for use in various environments. For instance, the screen has an ambient light sensor that adjusts the screen's brightness according to the amount of light in the room. This feature ensures that you always view the best quality image possible regardless of the lighting conditions in your room.Moreover, the kemtron screen also comes with a range of connectivity options, including HDMI, VGA, USB, and ethernet. These features make it easy to connect your preferred device or network seamlessly. You can quickly connect your smartphone, laptop, or gaming console to the screen for seamless entertainment and work purposes.The company behind the kemtron 48-inch screen is known for its high-quality products. The company has a team of experienced professionals who are committed to providing their clients with cutting-edge technology and innovative products. Their dedication to customer satisfaction has earned them a reputation as one of the go-to companies when it comes to advanced visual solutions.Their expertise in design, technology, and engineering is evident in the kemtron 48-inch screen, making it a must-have for anyone who wants to enjoy the best viewing experience. The company's commitment to innovation means that customers can expect nothing but high-quality products that are always cutting-edge.In conclusion, with its high resolution, excellent picture quality, and a range of features that make it ideal for use in various environments, the kemtron 48-inch screen is the perfect investment for anyone who cares about their content's visual display. The screen's impeccable design, combined with the company's expertise in technology and design, make this a must-have product for those looking for the best in the visual entertainment and work world. Get yours today and start experiencing the best that technology has to offer.