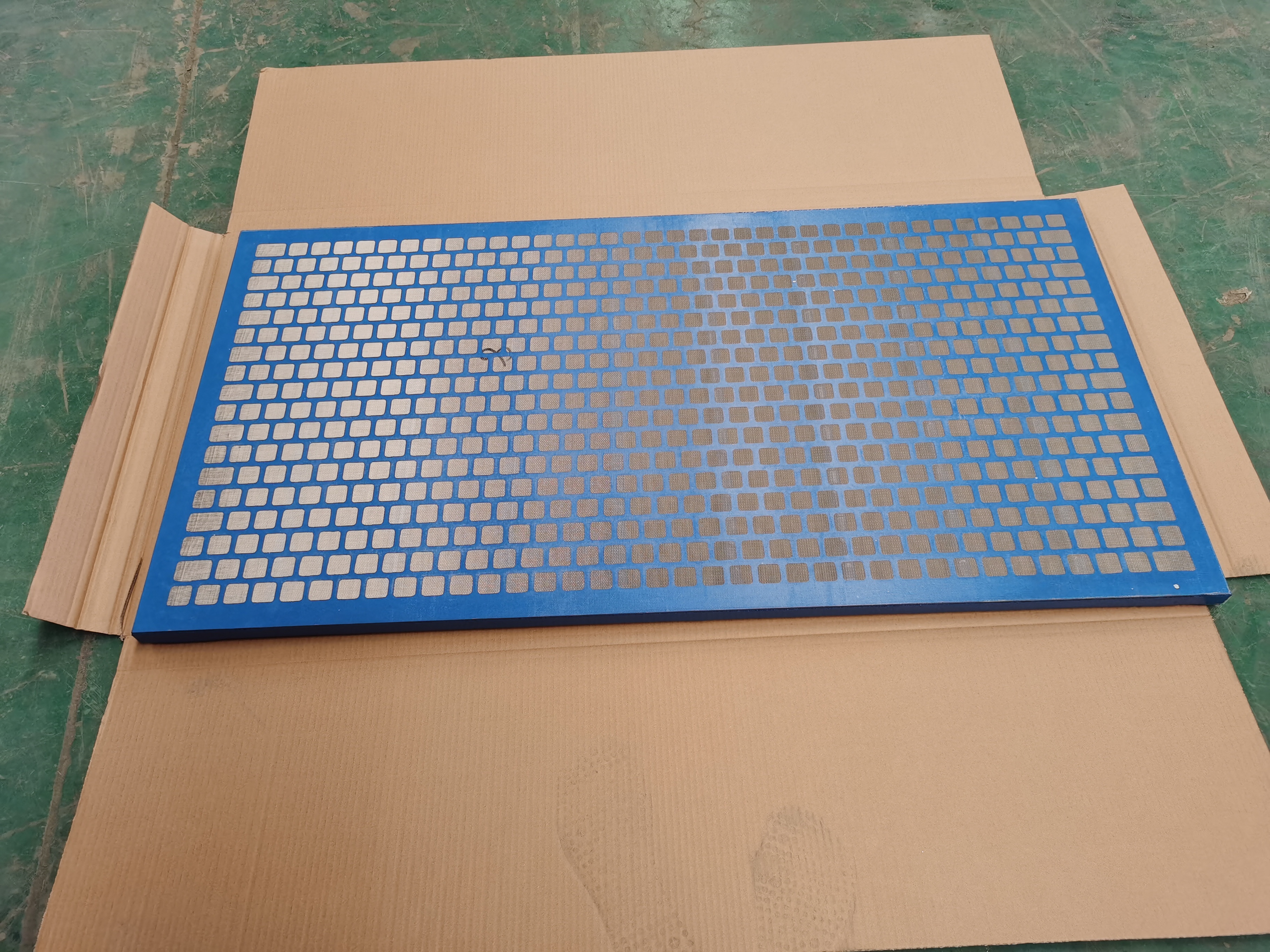

King Cobra/Hybrid Composite Frame Shaker Screen - Latest News and Updates

By:Admin

The global oil and gas industry has long been searching for ways to improve efficiency and reduce costs in their drilling operations. One crucial part of the drilling process is the use of shaker screens, which are designed to separate solids from drilling mud. That's where the new King Cobra/Hybrid Composite Frame Shaker Screen comes in.

This innovative product is set to revolutionize the oil and gas industry, providing drilling companies with a more efficient and cost-effective solution for their shaker screen needs. The King Cobra/Hybrid Composite Frame Shaker Screen is designed to deliver superior performance and durability, making it the perfect choice for challenging drilling environments.

The key to the success of the King Cobra/Hybrid Composite Frame Shaker Screen is its unique design, which combines the best features of both metal and composite frame shaker screens. This hybrid construction allows for maximum strength and longevity, while also providing the flexibility and efficiency of a composite frame screen.

The King Cobra/Hybrid Composite Frame Shaker Screen is also engineered to provide a larger usable screen area, resulting in increased fluid handling capacity and improved solids control. This means less downtime and fewer interruptions during drilling operations, leading to significant cost savings for drilling companies.

In addition to its superior performance, the King Cobra/Hybrid Composite Frame Shaker Screen is also designed with ease of use in mind. Its lightweight construction and simple installation process make it a hassle-free solution for drilling companies, allowing them to quickly and efficiently replace worn-out screens and get back to work.

The company behind this groundbreaking product is a leading manufacturer of drilling fluid management equipment, with a strong reputation for delivering high-quality products and innovative solutions to the oil and gas industry. With a commitment to excellence and a focus on customer satisfaction, the company has quickly become a trusted partner for drilling companies around the world.

By continuously investing in research and development, the company has been able to stay ahead of the curve and consistently deliver cutting-edge products that meet the evolving needs of the industry. The launch of the King Cobra/Hybrid Composite Frame Shaker Screen is a testament to the company's dedication to innovation and its ongoing efforts to provide the industry with the best possible solutions.

With the introduction of the King Cobra/Hybrid Composite Frame Shaker Screen, drilling companies now have access to a game-changing product that offers unmatched performance, durability, and cost-effectiveness. This innovative solution is set to redefine the standards for shaker screen technology and revolutionize the way drilling operations are conducted.

As the global oil and gas industry continues to face new challenges and demands, the need for innovative solutions like the King Cobra/Hybrid Composite Frame Shaker Screen has never been greater. With its unparalleled performance and advanced design, this revolutionary product is poised to make a significant impact on the industry and help drilling companies achieve greater efficiency and success in their operations.

In conclusion, the King Cobra/Hybrid Composite Frame Shaker Screen represents a major leap forward in shaker screen technology, offering unparalleled performance and durability for drilling operations. With its innovative design and advanced features, this groundbreaking product is set to become an essential tool for drilling companies worldwide as they strive to improve efficiency and reduce costs in their operations.

Company News & Blog

High-Quality Vibrating Filter Sieve for Liquid Shaker and Soybean Milk Screening

Vibrating Filter Sieve Liquid Sieve Shaker Soybean Milk Vibro Shifter Machine Vibrating Screen has always been known for its innovative and high-quality products in the field of industrial sieving and filtration. The company has built a strong reputation for providing reliable and efficient equipment that meets the needs of various industries worldwide.With their continuous dedication to research and development, the company has recently launched a new and improved line of vibrating filter sieves, liquid sieve shakers, soybean milk vibro shifter machines, and vibrating screens. These new products are designed to offer enhanced performance, increased productivity, and more precise results for their customers.The vibrating filter sieve is a versatile and efficient machine that is used for liquid-solid separation in various industries such as food and beverage, pharmaceuticals, chemicals, and more. It is capable of handling a wide range of materials and can effectively remove impurities and contaminants to ensure the quality and purity of the end product.The liquid sieve shaker is another essential equipment for industries that require accurate particle size analysis and separation of solids from liquids. It is equipped with advanced technology to offer consistent and reliable results, making it an indispensable tool for quality control and research and development purposes.The soybean milk vibro shifter machine is designed specifically for the processing of soybean milk and other similar products. It is capable of efficiently separating the liquid from solids and ensuring a smooth and uniform texture, making it an ideal choice for manufacturers in the dairy and beverage industry.Lastly, the vibrating screen is a widely used machine for the grading and screening of materials in industries such as mining, construction, and agriculture. The new and improved vibrating screen from the company provides higher efficiency and better performance, allowing for faster processing and higher throughput.In addition to the innovative features and improved performance, the new line of products also boasts a user-friendly design, easy maintenance, and long-lasting durability. This ensures that customers can benefit from reduced downtime, lower operating costs, and overall improved operational efficiency.The spokesperson for the company expressed their excitement about the launch of these new products and highlighted the company's commitment to providing innovative solutions to meet the evolving needs of their customers. They emphasized the extensive research and development that went into the design and engineering of these products, and the company's dedication to maintaining their position as a leader in the industry.As a global supplier of industrial sieving and filtration equipment, the company has a strong presence in various markets around the world, serving a wide range of industries and applications. Their products are renowned for their reliability, efficiency, and quality, making them a trusted choice for businesses looking to optimize their processes and enhance their product quality.The introduction of the new line of vibrating filter sieves, liquid sieve shakers, soybean milk vibro shifter machines, and vibrating screens further solidifies the company's commitment to providing cutting-edge solutions that help their customers stay ahead in their respective industries.As customer satisfaction has always been a top priority for the company, they have also made sure to offer comprehensive support and after-sales service for their products, ensuring that their customers can maximize the benefits of their investment and rely on their equipment for years to come.With the launch of these new products, the company is poised to continue their legacy of delivering high-quality, reliable, and efficient solutions to industries worldwide. Their dedication to innovation, quality, and customer satisfaction solidifies their position as a leader in the field of industrial sieving and filtration.

Latest Updates on High-Quality Stainless Steel Shaker Screens

Stainless Steel Shaker Screen Plays a Crucial Role in Oil and Gas DrillingThe importance of high-quality shaker screens in the oil and gas drilling industry is undeniable. They are vital in the separation of drilling fluids and solids during the drilling process. Therefore, it is imperative to have reliable, durable shaker screens that can withstand the rigorous demands of the industry.{The company} is a leading manufacturer of shaker screens and other equipment for the oil and gas industry. The company has established itself as a trusted brand in the industry, providing innovative solutions that meet the needs of customers.The {company} stainless steel shaker screen is one of the most popular products in its lineup. The screen is known for its high efficiency and durability, making it a top choice for drilling operations. It is made of high-quality stainless steel wire mesh and features a unique frame design that ensures maximum screen life and performance.One of the key features of the stainless steel shaker screen is its ability to withstand high temperatures and corrosive materials. This is crucial in the drilling process because the drilling fluids contain various chemicals, which can be highly corrosive and can damage the screen quickly. The {company} shaker screen can handle these harsh conditions without compromising its performance.Another advantage of the {company} stainless steel shaker screen is its superior filtration capabilities. The screen's unique design allows for maximum fluid handling capacity, ensuring that the drilling fluids and solids are separated efficiently. This not only improves the performance of the drilling process but also helps to reduce costs associated with replacing shaker screens frequently.In addition to its technical features, the {company} stainless steel shaker screen is also designed with ease of use in mind. The screen can be easily installed and removed from the shaker, reducing downtime and increasing efficiency.The {company} stainless steel shaker screen is available in a range of sizes and configurations to meet the diverse needs of customers. Whether it is a small-scale drilling operation or a large-scale project, the {company} shaker screen can provide the necessary performance and reliability needed to get the job done.The success of any drilling operation relies on the quality and performance of the equipment used, and the {company} stainless steel shaker screen is an excellent example of equipment that can make a significant difference. With its durable design, superior filtration capabilities, and ease of use, the {company} shaker screen has become a popular choice for drilling companies around the world.In conclusion, the importance of high-quality shaker screens in the oil and gas drilling industry cannot be overstated. The {company} stainless steel shaker screen is an outstanding example of equipment that can make a significant difference in the success of drilling operations. Its durability, filtration capabilities, and ease of use are just a few of the reasons why it has become a trusted choice for drilling companies worldwide.

Latest Innovation in Shaker Screen Technology: Derrick's HYP PMD Shaker Screen

Derrick Corporation, a global leader in the production of high-performance separation and filtration equipment, has recently introduced its latest innovation in solids control technology - the HYP PMD Shaker Screen. This new product is set to revolutionize the industry with its advanced features and superior performance.The HYP PMD Shaker Screen is designed to provide enhanced efficiency and durability, making it a standout choice for operators looking to optimize their solids control operations. The screen is built with a unique composite frame that offers increased structural integrity and longevity, while also reducing weight and overall cost. This innovative design ensures that the screen can withstand the demanding conditions of drilling operations, resulting in reduced downtime and maintenance costs.In addition to its robust construction, the HYP PMD Shaker Screen also features an advanced pretension screen design that maximizes the usable screen area, leading to improved solids removal and higher fluid processing capacity. This design allows for increased productivity and efficiency, ultimately leading to cost savings and improved overall operational performance.One of the key advantages of the HYP PMD Shaker Screen is its ability to deliver exceptional cuttings dryness, thanks to the proprietary screen cloth technology employed by Derrick Corporation. This technology ensures that the screen can effectively separate and remove solids from drilling fluids, resulting in drier cuttings and reduced waste disposal costs. Additionally, the high-quality screen cloth is engineered to withstand the abrasive nature of drilling fluids, ensuring prolonged screen life and consistent performance.Derrick Corporation is proud to offer the HYP PMD Shaker Screen as part of its comprehensive range of solids control solutions, which also includes shale shakers, desanders, desilters, and other related equipment. With decades of experience in the industry, Derrick Corporation has established itself as a trusted partner for operators seeking to improve their solids control and waste management processes.“At Derrick Corporation, we are dedicated to pushing the boundaries of innovation to deliver cutting-edge solutions that address the evolving needs of the industry,” said a spokesperson for the company. “The introduction of the HYP PMD Shaker Screen is a testament to our commitment to providing our customers with reliable, high-performance equipment that helps them achieve their operational goals.”The HYP PMD Shaker Screen is now available for purchase and is supported by Derrick Corporation's global network of service centers, ensuring that customers can access prompt technical support and aftermarket services wherever their operations may be located. The company is also offering comprehensive training and education programs to help customers optimize the performance of the HYP PMD Shaker Screen and other Derrick equipment.As the industry continues to demand more efficient and effective solids control solutions, the HYP PMD Shaker Screen is poised to make a significant impact by providing operators with a reliable, high-performance tool for their operations. With its advanced features, durable construction, and superior performance, this innovative product is set to raise the bar for solids control technology and lead the way to a more efficient and sustainable future for the industry.

Scalping Screen for VSM300: News and Updates

Brandt / NOV VSM300 Scalping Screen is a high-efficiency, multi-functional scalping screen. It is designed to provide the ultimate in flexibility and adaptability. The screen is capable of handling a wide range of material from heavy duty scalping to precision screening. This makes it an ideal solution for a variety of industries including mining, aggregate, construction, and recycling.The key feature of the Brandt / NOV VSM300 Scalping Screen is its versatility. It can effectively screen a wide range of materials including aggregates, coal, and ores. This flexibility makes it an invaluable tool for any operation involved in material handling.In addition to its versatility, the Brandt / NOV VSM300 Scalping Screen is also known for its efficiency. The screen is equipped with high-performance, heavy-duty bearings that provide long-term reliability and low maintenance. This ensures that the screen can operate at maximum efficiency with minimal downtime.The screen is also designed with ease of use in mind. It features a user-friendly control system that allows operators to easily adjust settings and configure the screen to meet their specific needs. This makes the Brandt / NOV VSM300 Scalping Screen an ideal choice for operations of all sizes.In addition to its performance and ease of use, the Brandt / NOV VSM300 Scalping Screen is also designed with durability in mind. It is constructed with high-quality materials and components that are built to withstand the rigors of heavy-duty use. This ensures that the screen will continue to perform reliably even in the most demanding of environments.To support the efficient operation of the Brandt / NOV VSM300 Scalping Screen, the company provides comprehensive service and support. This includes installation, training, and ongoing maintenance to ensure that the screen continues to perform at its best.The Brandt / NOV VSM300 Scalping Screen is backed by a team of industry experts who are dedicated to providing superior customer service. They are committed to understanding the unique needs of each customer and providing tailored solutions to meet those needs.In summary, the Brandt / NOV VSM300 Scalping Screen is a high-performance, versatile, and durable screening solution that is ideal for a wide range of industries. Its efficiency, ease of use, and durability make it a valuable asset for any operation involved in material handling.In addition to its impressive performance, the company is also committed to providing excellent customer service and support. This ensures that customers can rely on the Brandt / NOV VSM300 Scalping Screen to meet their needs now and in the future.

Durable Steel Frame Screen: A Reliable Solution for Screening Needs

GNZS-752 Steel Frame Screen has been making waves in the oil and gas industry with its innovative and efficient solution for solids control and waste management. The company, which was established in 2010, has quickly risen to become a leading provider of high-quality solids control equipment and services.The GNZS-752 Steel Frame Screen is a vital component of the company's comprehensive line of solids control equipment. It is designed to effectively remove solids and impurities from drilling fluids, ensuring that the fluids remain in optimal condition for the duration of the drilling process. The screen is constructed with high-quality steel frame and adheres to strict manufacturing standards, making it durable and long-lasting even in the most demanding drilling conditions.One of the key features of the GNZS-752 Steel Frame Screen is its advanced composite frame technology. This technology allows for increased screen life and fluid-handling capacity, ultimately leading to improved solids control efficiency. Additionally, the screen is designed for quick and easy installation, reducing downtime and maximizing operational efficiency for drilling operations.The GNZS-752 Steel Frame Screen is compatible with a wide range of shakers, allowing for seamless integration into existing solids control systems. This versatility makes it an ideal solution for drilling contractors and operators looking to enhance their solids control processes.In addition to its innovative products, the company behind the GNZS-752 Steel Frame Screen is known for its commitment to customer satisfaction and technical support. The company's team of experienced professionals are dedicated to providing exceptional service and support to clients, ensuring that their solids control needs are met with the highest level of expertise and efficiency.Furthermore, the company has established a global presence, with a network of distributors and partners spanning across the world. This global reach allows for quick and efficient access to the GNZS-752 Steel Frame Screen and other solids control equipment, regardless of the location of the drilling operation.The GNZS-752 Steel Frame Screen has already garnered praise from industry professionals for its outstanding performance and reliability. Its advanced technology and durable construction have made it a preferred choice for drilling contractors and operators around the world.With a proven track record of delivering high-quality solids control solutions, the company behind the GNZS-752 Steel Frame Screen has solidified its position as a leader in the industry. As the demand for efficient solids control and waste management solutions continues to grow, the company remains dedicated to providing innovative, reliable, and cost-effective solutions for the oil and gas industry.In conclusion, the GNZS-752 Steel Frame Screen is a testament to the company's commitment to excellence and innovation in the field of solids control. With its advanced technology, durable construction, and global presence, the screen is set to continue making a significant impact in the industry, meeting the needs of drilling contractors and operators around the world.

Steel Frame Shaker Screen: A Durable and Efficient Solution

DFTS Steel Frame Shaker Screen, a leading provider of high-quality shaker screens for the oil and gas industry, has recently announced the launch of their latest product, the DFTS Steel Frame Shaker Screen. This innovative product is set to revolutionize the oil and gas drilling process with its advanced technology and reliable performance.The DFTS Steel Frame Shaker Screen is designed to effectively separate solids and fluids in the drilling mud, ensuring that the drilling operation runs smoothly and efficiently. This new addition to the DFTS product line is built with a strong and durable steel frame, allowing it to withstand the harsh conditions of drilling operations without compromising its performance.With a focus on providing top-notch quality products, DFTS has garnered a strong reputation in the industry for their high-performance shaker screens. The company takes pride in their commitment to innovation and excellence, which is reflected in the latest DFTS Steel Frame Shaker Screen. This product is the result of extensive research and development, aimed at meeting the evolving needs of the oil and gas industry.DFTS has a long-standing history of delivering reliable and cost-effective solutions to their clients. The company understands the challenges faced by drilling operations and is dedicated to providing products that address these challenges. The DFTS Steel Frame Shaker Screen is a testament to their dedication to delivering exceptional products that enhance operational efficiency and productivity.One of the key features of the DFTS Steel Frame Shaker Screen is its superior performance in separating solids from drilling mud. This is essential in maintaining the overall integrity of the drilling process, as it prevents the build-up of solids that can hinder the operation. The screen’s advanced design and construction ensure that it effectively filters out a wide range of solid particles, resulting in a cleaner and more efficient drilling mud.Furthermore, the DFTS Steel Frame Shaker Screen is designed for easy installation and maintenance, reducing downtime and operational costs. The company has always placed a strong emphasis on user-friendly products, and this latest offering is no exception. With its simple and efficient design, this shaker screen is set to streamline the screening process, making it easier for drilling operators to maintain the equipment and keep it in optimal working condition.In addition to its performance and user-friendly design, the DFTS Steel Frame Shaker Screen is also built for durability. The high-quality materials and construction ensure that the screen can withstand the toughest drilling conditions, providing long-term reliability and cost-efficiency. This is a critical factor in the oil and gas industry, where equipment reliability is paramount to the success of drilling operations.The launch of the DFTS Steel Frame Shaker Screen is a significant milestone for DFTS, as it further solidifies their position as a leading provider of shaker screens for the oil and gas industry. The company’s commitment to quality, innovation, and customer satisfaction has been the driving force behind their success, and this latest product is a testament to their dedication to excellence.In conclusion, the DFTS Steel Frame Shaker Screen is poised to make a significant impact on the oil and gas industry with its advanced technology, reliable performance, and durable construction. DFTS continues to set the standard for excellence in shaker screen solutions, and this latest addition to their product line is a testament to their ongoing commitment to meeting the evolving needs of the industry. With the launch of the DFTS Steel Frame Shaker Screen, DFTS reaffirms their position as a trusted partner for drilling operators seeking top-quality solutions for their operations.

High Quality 48 PMD Shaker Screen for Derrick Model

Derrick Corporation, a global leader in manufacturing high-performance separation and filtration equipment, has recently introduced the Derrick 48 PMD Shaker Screen, the latest addition to their extensive product line. This new shaker screen is designed to provide superior performance and longevity, meeting the growing demands of the oil and gas industry.The Derrick 48 PMD Shaker Screen is engineered with advanced technology and exceptional quality materials to ensure efficient and effective solids control. It features a unique pyramid design that increases the usable screen area, providing better capacity and longer screen life. This innovative design allows for increased fluid handling capacity and improved solids removal, ultimately leading to higher productivity and cost savings for the operators.With a focus on durability and reliability, the Derrick 48 PMD Shaker Screen is built to withstand the harsh operating conditions of drilling operations. Its robust construction and precise manufacturing process ensure consistent and reliable performance, even in the most challenging environments. This makes it an ideal choice for operators looking to optimize their solids control processes and reduce overall operating costs.In addition to its exceptional performance, the Derrick 48 PMD Shaker Screen is designed for easy installation and maintenance. Its user-friendly design allows for quick and simple screen replacement, minimizing downtime and maximizing operational efficiency. This feature is particularly beneficial for operators looking to streamline their maintenance procedures and enhance overall equipment uptime.Moreover, the Derrick 48 PMD Shaker Screen is compatible with a wide range of shale shakers, making it a versatile solution for various drilling applications. Its adaptability and flexibility make it an attractive option for operators seeking a reliable and cost-effective solids control solution that can be easily integrated into their existing equipment fleet.Derrick Corporation, with over 70 years of experience in the industry, has built a solid reputation for delivering innovative and high-quality separation and filtration solutions. The introduction of the Derrick 48 PMD Shaker Screen further solidifies their commitment to providing cutting-edge technologies that address the evolving needs of the oil and gas industry.The company’s dedication to research and development, coupled with their extensive industry expertise, has positioned Derrick Corporation as a trusted partner for operators seeking best-in-class solids control and filtration solutions. Their relentless pursuit of excellence and customer-centric approach have made them a preferred choice for companies looking to optimize their drilling operations and maximize performance.In conclusion, the Derrick 48 PMD Shaker Screen represents a significant advancement in solids control technology, offering unmatched performance, durability, and versatility. Backed by Derrick Corporation’s unparalleled reputation and commitment to innovation, this new shaker screen is set to redefine industry standards and empower operators to achieve greater efficiency and productivity in their operations. As the oil and gas industry continues to evolve, Derrick Corporation remains at the forefront, providing cutting-edge solutions that address the dynamic challenges of the industry.

Innovative vibrating screen technology revolutionizes industrial sieving requirements

Vibrating screens are widely used in industries such as mining, aggregate, chemical, and recycling to separate materials by size. They play a crucial role in improving the efficiency and quality of production processes. One company that has been at the forefront of producing high-quality vibrating screens is {}.{} is a leading manufacturer of vibrating screens that are known for their durability, reliability, and high performance. The company has been in the business for over two decades and has established a strong reputation for delivering top-notch products to its customers.The company takes pride in its state-of-the-art manufacturing facilities and a team of experienced engineers and technicians who are dedicated to producing innovative and cost-effective solutions for various industries. With a focus on research and development, {} constantly strives to improve its products and stay ahead of the competition.One of the key features of {}'s vibrating screens is their modular design, which allows for easy installation, maintenance, and replacement of parts. This not only reduces downtime for the customers but also provides the flexibility to customize the screens according to their specific requirements.The screens are designed to withstand the harsh conditions of industrial operations and are built with high-quality materials that ensure longevity and minimal wear and tear. Additionally, {}'s vibrating screens are equipped with advanced technologies that enhance their performance and efficiency.In addition to standard vibrating screens, {} also offers custom solutions to meet the unique needs of its customers. Whether it's a specific size, capacity, or material requirement, the company has the capability to design and manufacture tailor-made vibrating screens.Customer satisfaction is at the core of {}'s business philosophy, and the company strives to provide excellent after-sales support. From installation and commissioning to troubleshooting and maintenance, {}'s team of experts is always ready to assist its customers and ensure that their vibrating screens operate at peak performance.With a strong presence in the global market, {} has built a vast network of clients who rely on its products for their production processes. The company takes pride in its ability to meet the diverse needs of different industries and deliver solutions that exceed expectations.In line with its commitment to sustainability, {} also focuses on developing energy-efficient vibrating screens that help its customers reduce their carbon footprint and operating costs. This is in line with the company's vision of contributing to a greener and more sustainable future for the industries it serves.As a leading manufacturer of vibrating screens, {} continues to push the boundaries of innovation and set new standards for quality and performance. With a focus on customer-centric solutions and a dedication to excellence, the company remains a trusted partner for industries looking to optimize their material separation processes.The future looks bright for {} as it continues to expand its product range and explore new opportunities in the global market. With a strong foundation built on reliability, durability, and innovation, the company is well-positioned to remain at the forefront of the vibrating screen industry for years to come.

High-quality Mongoose PT Shaker Screen for Effective Filtration

Swaco Mongoose PT Shaker Screen, a leading provider of innovative solutions for the oil and gas industry, has recently unveiled a groundbreaking new product that is set to revolutionize the industry. The company’s new shaker screen, which has been designed and manufactured to the highest standards of quality and performance, promises to deliver unparalleled efficiency and reliability for oil and gas drilling operations.With a focus on providing advanced technology and superior performance, Swaco Mongoose PT Shaker Screen has quickly become a preferred choice for oil and gas companies around the world. The company’s commitment to innovation and customer satisfaction has positioned them as a leader in the industry, and their latest product launch is further evidence of their dedication to excellence.The new shaker screen is designed to deliver exceptional performance in the most demanding drilling conditions, providing operators with the ability to achieve higher levels of efficiency and productivity. With its innovative design and advanced materials, the screen offers improved solids control and separation, resulting in cleaner drilling fluid and reduced waste. This not only improves operational efficiency but also reduces costs and environmental impact.Swaco Mongoose PT Shaker Screen’s commitment to quality is evident in every aspect of their products, from the selection of materials to the precision engineering and manufacturing processes. The company’s dedication to excellence ensures that their products consistently meet the highest standards of performance, reliability, and durability, providing customers with confidence and peace of mind.In addition to the superior performance of the new shaker screen, Swaco Mongoose PT Shaker Screen also offers a range of support services to ensure the success of their customers’ operations. Their team of experts provides technical assistance, maintenance, and training, empowering operators to maximize the potential of their equipment and achieve optimal results.The launch of this groundbreaking new product is a testament to Swaco Mongoose PT Shaker Screen’s commitment to innovation and continuous improvement. By leveraging their expertise, experience, and industry knowledge, the company has developed a product that will undoubtedly raise the bar for performance and reliability in the oil and gas industry.As the oil and gas industry continues to evolve, the demand for advanced technology and solutions that can deliver superior performance and efficiency has never been greater. With the introduction of their new shaker screen, Swaco Mongoose PT Shaker Screen has once again proven that they are at the forefront of the industry, providing solutions that meet the evolving needs of their customers and the industry as a whole.For companies operating in the oil and gas industry, the new shaker screen from Swaco Mongoose PT Shaker Screen represents an exciting opportunity to enhance operational efficiency, reduce costs, and improve environmental sustainability. With its unparalleled performance and reliability, the product is set to become an essential tool for operators seeking to maximize their drilling operations.In conclusion, Swaco Mongoose PT Shaker Screen’s dedication to excellence and innovation has once again been demonstrated with the launch of their new shaker screen. The company’s commitment to delivering superior performance, reliability, and support services has positioned them as a trusted partner for oil and gas companies around the world. As the industry continues to evolve, Swaco Mongoose PT Shaker Screen remains at the forefront, providing solutions that empower operators to achieve their operational goals and drive success in their businesses.

Replacement Shaker Screen for King Cobra/Hybrid Models

Due to the increasing demand for efficient and reliable equipment in the oil and gas industry, our company is proud to introduce the latest innovation in shaker screen technology - the Replacement Shaker Screen for Brandt King Cobra/Hybrid. This new product is designed to revolutionize the solids control process and improve the overall performance of shakers in drilling operations.With a focus on durability, longevity, and superior performance, our Replacement Shaker Screen for Brandt King Cobra/Hybrid is manufactured using the highest quality materials and the latest in screen manufacturing technology. This ensures that our screens are able to withstand the most demanding drilling conditions, while also delivering consistent and reliable performance.The Replacement Shaker Screen for Brandt King Cobra/Hybrid is engineered to provide increased throughput, longer screen life, and improved conductance, resulting in more effective solid removal and drier discharge solids. This ultimately leads to reduced operating costs and improved efficiency in the drilling process.Our company understands the importance of reliability and efficiency in drilling operations, which is why we have invested heavily in research and development to create the most advanced shaker screens on the market. The Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to our commitment to providing our customers with the best possible solutions for their solids control needs.In addition to the exceptional performance of our shaker screens, our company also prides itself on providing unparalleled customer service and support. We work closely with our customers to understand their specific requirements and to ensure that our products meet and exceed their expectations. Our team of experienced professionals is dedicated to providing technical support, troubleshooting, and on-site assistance to help our customers get the most out of our products.Furthermore, our company is dedicated to environmental sustainability, and our Replacement Shaker Screen for Brandt King Cobra/Hybrid is designed with this in mind. By improving the efficiency of solids control and reducing waste, our screens contribute to a more environmentally friendly drilling process.With a strong focus on quality, performance, and customer satisfaction, our company is proud to offer the Replacement Shaker Screen for Brandt King Cobra/Hybrid as the latest addition to our range of industry-leading solids control solutions. We are confident that this new product will set a new standard for shaker screen performance and reliability in the oil and gas industry.As we continue to innovate and develop new technologies, our goal is to remain at the forefront of the industry and to provide our customers with the most advanced and effective solutions for their solids control needs. We are dedicated to driving progress and excellence in the oil and gas sector, and the Replacement Shaker Screen for Brandt King Cobra/Hybrid is a testament to our commitment to delivering superior products and service.In conclusion, the Replacement Shaker Screen for Brandt King Cobra/Hybrid represents a significant advancement in shaker screen technology, and our company is proud to bring this innovative solution to the market. With its exceptional performance, durability, and environmental benefits, this new product is set to improve the efficiency and reliability of solids control in drilling operations. We are excited to offer this revolutionary shaker screen to our customers and to continue leading the way in providing cutting-edge solutions for the oil and gas industry.