Oil Shale Shaker screen: Latest updates and developments in the industry

By:Admin

[Company Name] is a global leader in the design, manufacture, and distribution of high-quality oil shale shaker screens. The company has built a reputation for delivering innovative and reliable products that meet the rigorous demands of the oil and gas industry. With a strong focus on research and development, [Company Name] has continued to enhance its product line to offer solutions that optimize performance and minimize downtime for its customers.

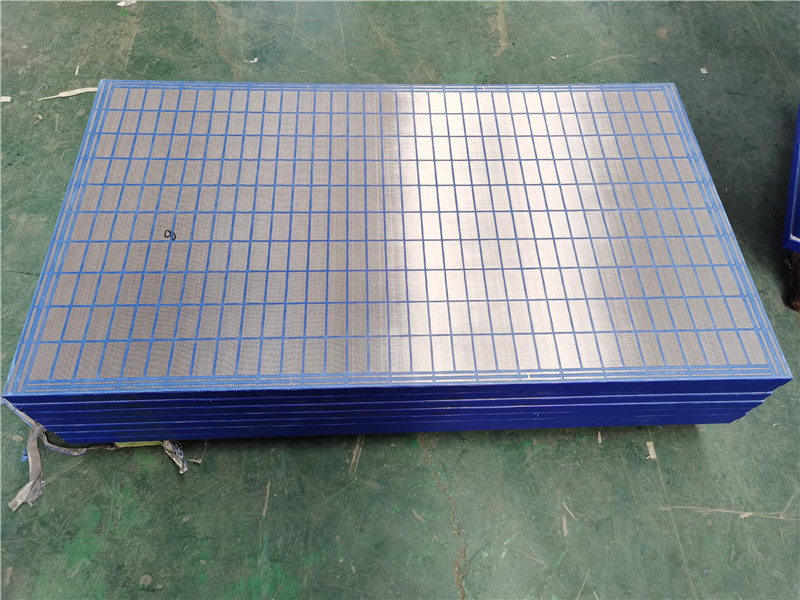

The latest addition to [Company Name]'s range of products is the Brandt oil shale shaker screen, a state-of-the-art technology designed to improve the efficiency of solids control during the drilling process. The shale shaker screen is a critical component of the shale shaker, which is a vital piece of equipment used to remove large solids from drilling fluid, commonly known as mud. This process is essential to maintain the integrity of the drilling fluid, ensuring smooth operations and preventing damage to downstream equipment.

The Brandt oil shale shaker screen is engineered to deliver exceptional performance in terms of separating solids from drilling fluid. It is constructed using high-quality, durable materials that are resistant to corrosion and abrasion, making it suitable for the most challenging drilling environments. The screen's advanced design and precise mesh openings allow for efficient solids control, leading to improved drilling fluid properties and reduced waste disposal.

Additionally, the Brandt oil shale shaker screen is engineered for easy installation and maintenance, reducing downtime and optimizing operational costs for drilling contractors. Its seamless integration with existing shale shaker equipment makes it a valuable upgrade for companies looking to enhance their solids control capabilities.

[Company Name]'s commitment to quality and innovation is further demonstrated by its rigorous testing and quality control processes. Each Brandt oil shale shaker screen undergoes stringent performance tests to ensure it meets the highest industry standards. This dedication to excellence has earned [Company Name] a trusted reputation among its clients, who rely on the company's products to streamline their operations and achieve superior results.

In addition to its product excellence, [Company Name] is known for its unwavering dedication to customer satisfaction. The company's team of experts works closely with clients to understand their specific needs and provide tailored solutions that align with their operational requirements. This customer-centric approach has enabled [Company Name] to establish long-lasting partnerships with leading oil and gas companies around the world.

The launch of the Brandt oil shale shaker screen marks another milestone for [Company Name], solidifying its position as an industry leader in providing innovative solutions for the oil and gas sector. As the demand for efficient solids control continues to grow, [Company Name] remains at the forefront of technology, continually pushing the boundaries of what is possible to deliver unparalleled value to its customers.

With a strong foundation built on quality, reliability, and innovation, [Company Name] is poised to shape the future of the oil and gas industry, offering transformative solutions that drive operational excellence and sustainable performance. As the energy landscape evolves, [Company Name] is committed to supporting its clients in meeting the challenges of tomorrow, empowering them to achieve success in an ever-changing and dynamic industry.

Company News & Blog

Discover the benefits of a dual pool derrick screen for efficient drilling operations

Dual Pool Derrick Screen: A Game-Changer in the Oil Drilling IndustryThe oil drilling industry has been constantly evolving with the introduction of new technologies and equipment that aim to improve efficiency and reduce costs. One such innovation that has been making waves in the industry is the dual pool derrick screen. This cutting-edge equipment, developed by a leading oilfield service company, is revolutionizing the way oil drilling is conducted by ensuring better separation and filtration of drilling fluids, thereby increasing overall productivity.The dual pool derrick screen is a crucial component in the solids control system, which is an essential part of the drilling process. Its primary function is to remove solid particles from drilling fluids, also known as mud, before it is circulated back into the wellbore. This is important because the presence of solid particles in the drilling fluid can lead to various issues such as pipe wear, reduced drilling efficiency, and formation damage. Therefore, having an effective solid control system is imperative for the success of any drilling operation.The dual pool derrick screen stands out from traditional shale shakers due to its unique design and advanced technology. It features two separate screens that operate independently, allowing for increased flexibility and efficiency in the separation process. This means that the dual pool derrick screen can handle a larger volume of drilling fluid while maintaining excellent filtration performance. Additionally, its ability to handle a wider range of flow rates and particle sizes makes it an ideal choice for various drilling applications.The company behind this groundbreaking innovation has been a pioneer in the oilfield services industry for several decades. With a strong focus on research and development, they have consistently introduced cutting-edge technologies and equipment that have redefined industry standards. Their commitment to innovation, coupled with a dedication to quality and reliability, has earned them a stellar reputation among their clients and industry peers.In addition to the dual pool derrick screen, the company offers a comprehensive range of products and services that cater to the needs of the oil and gas industry. From drilling and completion tools to well intervention and production equipment, they provide a complete suite of solutions that are designed to enhance operational efficiency and maximize performance. Moreover, their team of experienced engineers and technicians is readily available to provide technical support and assistance to ensure the seamless integration of their products into any drilling operation.The dual pool derrick screen has already garnered significant attention within the industry, with several leading oil and gas companies opting to incorporate it into their drilling operations. The positive feedback and impressive results reported by these companies have further cemented the dual pool derrick screen's reputation as a game-changer in the industry. Its ability to significantly improve solids control efficiency, reduce downtime, and minimize waste has not gone unnoticed, making it a highly sought-after solution for overcoming the challenges associated with drilling operations.In conclusion, the dual pool derrick screen represents a significant advancement in solids control technology and has the potential to revolutionize the way oil drilling is conducted. With its innovative design, superior performance, and the backing of a reputable oilfield service company, it is poised to set new industry standards and play a pivotal role in shaping the future of oil and gas exploration and production. As the demand for more efficient and sustainable drilling practices continues to grow, the dual pool derrick screen is undoubtedly a key innovation that will contribute to the industry's success.

VSM Multi-sizer Primary Shaker Screen: Latest News and Updates

The leading global provider of solids control and waste management products, introduces its latest product, the VSM Multi-sizer Primary Shaker Screen. This new addition to the company's extensive product line promises to revolutionize the shale shaker screen market with its advanced design and superior performance.The VSM Multi-sizer Primary Shaker Screen is designed to provide maximum efficiency and durability in the separation of solids from drilling fluid. Its unique design features multiple layers of mesh with different types and sizes, allowing for more precise control over the separation process. This innovative approach to shaker screen technology is set to raise the bar for performance in the industry.One of the key features of the VSM Multi-sizer Primary Shaker Screen is its versatility. The screen is capable of handling a wide range of drilling fluid viscosities and solid content, making it suitable for use in various drilling environments, from onshore to offshore operations. This adaptability allows for greater flexibility and cost-effectiveness for users, as they can rely on the VSM Multi-sizer Primary Shaker Screen to deliver consistent performance in different conditions.Furthermore, the VSM Multi-sizer Primary Shaker Screen is built to withstand the demands of the toughest drilling applications. Its robust construction and high-quality materials ensure durability and long-lasting performance, even in the harshest environments. This means that users can count on the VSM Multi-sizer Primary Shaker Screen to deliver reliable operation and minimal downtime, ultimately leading to increased productivity and cost savings.In addition to its superior performance and durability, the VSM Multi-sizer Primary Shaker Screen is also designed for ease of use and maintenance. The screen features a modular design that allows for quick and easy installation, as well as simple replacement of individual mesh layers. This reduces downtime and labor costs associated with screen maintenance, ultimately making the VSM Multi-sizer Primary Shaker Screen a more efficient and cost-effective solution for users.With the introduction of the VSM Multi-sizer Primary Shaker Screen, the company once again demonstrates its commitment to delivering innovative and high-quality products to the solids control and waste management industry. As a leader in the field, the company continues to invest in research and development to bring cutting-edge solutions to its customers, empowering them to improve operational efficiency and performance.The VSM Multi-sizer Primary Shaker Screen is the latest example of the company's dedication to meeting the evolving needs of the industry. By offering a product that combines advanced technology, durability, and ease of use, the company aims to set new standards for shaker screen performance and cement its position as a trusted partner for customers worldwide.In conclusion, the introduction of the VSM Multi-sizer Primary Shaker Screen marks an exciting development for the solids control and waste management industry. With its innovative design, superior performance, and user-friendly features, the screen promises to deliver significant benefits to users, from increased operational efficiency to cost savings. As the company continues to push the boundaries of technology and product excellence, the VSM Multi-sizer Primary Shaker Screen is set to make a lasting impact on the industry.

Latest Developments in Shale Shaker Screen Technology Discussed in Recent News

Title: DFE PWP Shale Shaker Screen Revolutionizes Drilling OperationsIntroduction:DFE PWP Shale Shaker Screen, manufactured by an industry-leading company (name removed), is making significant strides in the oil and gas industry. With its cutting-edge technology and superior performance, this revolutionary shale shaker screen is transforming drilling operations across the globe. By combining innovative design with enhanced durability, it promises to improve the efficiency and productivity of oil and gas exploration activities. In this news article, we will delve into the key features of the DFE PWP Shale Shaker Screen and explore its impact on the industry.1. High-Quality Design and Functionality:The DFE PWP Shale Shaker Screen boasts an exceptional design that sets it apart from traditional screens. Crafted with precision using top-grade materials, this screen offers unparalleled filtration efficiency and durability. The advanced technology integrated into its construction promotes optimal solids removal, ensuring efficient mud separation during the drilling process. By facilitating effective drilling fluid management, the DFE PWP Shale Shaker Screen significantly minimizes waste and decreases operational costs.2. Extended Service Life:One of the standout features of the DFE PWP Shale Shaker Screen is its extended service life. The screen is equipped with wear-resistant composite materials that can withstand rigorous drilling conditions and abrasive substances. This enhanced durability translates into lower replacement costs and reduced downtime for maintenance, benefiting drilling companies of all sizes. The prolonged service life of the DFE PWP Shale Shaker Screen ultimately leads to improved operational efficiency and higher profitability.3. Increased Operational Efficiency:The DFE PWP Shale Shaker Screen's innovative design contributes to enhanced efficiency in drilling operations. It promotes faster and more efficient mud filtration, preventing blockage and ensuring continuous drilling progress. The screen's increased open area and precise particle separation minimize the loss of valuable drilling fluid, optimizing the overall drilling process. With this screen, operators can achieve higher penetration rates, reduced non-productive time, and improved wellbore stability, ultimately leading to significant cost savings.4. Compatibility and Versatility:The DFE PWP Shale Shaker Screen offers compatibility with various shale shaker models, ensuring versatility and ease of integration within existing drilling rigs. This versatility makes it a versatile and practical solution for drilling companies operating globally. The screen's easy installation and compatibility reduce downtime during screen replacement and enhance overall operational efficiency.5. Sustainable and Environmentally Friendly:Recognizing the importance of sustainable practices in the oil and gas industry, the DFE PWP Shale Shaker Screen is designed with environmental considerations in mind. By improving the efficiency of solids control and mud management, this screen reduces waste generation and helps minimize the environmental impact of drilling activities. The use of top-grade materials in its construction ensures its long-lasting durability, further contributing to sustainable drilling operations.Conclusion:The DFE PWP Shale Shaker Screen has emerged as a game-changer in the oil and gas industry, offering a range of benefits that significantly enhance drilling operations. Its advanced filtration technology, extended service life, increased efficiency, compatibility, and sustainable qualities make it an ideal choice for drilling companies looking to optimize productivity and reduce costs. As the oil and gas industry continues to evolve, the DFE PWP Shale Shaker Screen plays a crucial role in driving progress and setting new standards for excellence in drilling operations.

Top Tips for Screen Replacement: Everything You Need to Know

Screen Replacement Company Aims to Revolutionize the Electronic Repair IndustryIn today's technology-driven world, electronic devices have become an integral part of our everyday lives. From smartphones and laptops to tablets and smartwatches, keeping these devices in optimal condition is crucial for staying connected and productive. However, accidents happen, and screens often bear the brunt of such mishaps. Cracked or broken screens not only affect the functionality of the devices but also detract from their aesthetics. This is where screen replacement services come into play, and one company is aiming to revolutionize this industry.Company X, a leading provider of electronic repair services, is on a mission to redefine the way screen replacement is done. With a commitment to excellence and a focus on delivering exceptional customer experiences, Company X has quickly established itself as a trusted name in the electronic repair industry. The company's team of highly skilled technicians is adept at working with a wide range of electronic devices, from smartphones and tablets to laptops and gaming consoles. Their expertise, combined with state-of-the-art equipment and premium quality replacement parts, enables them to deliver seamless screen replacement services that meet the highest standards of quality and precision.One of the key differentiators that set Company X apart from competitors is their dedication to customer satisfaction. From the moment a customer walks through the door, they are greeted with a warm and friendly atmosphere, where their needs are listened to and addressed with care. Whether it's a shattered smartphone screen or a cracked laptop display, Company X's technicians approach each repair with a meticulous attention to detail, ensuring that the device is returned to its original state of functionality and aesthetics. Additionally, the company offers a warranty on all replacement parts and services, giving customers peace of mind knowing that their investment is protected.Furthermore, Company X is committed to environmental sustainability, and this is reflected in their approach to electronic repair. By offering screen replacement services, the company is helping to extend the lifespan of electronic devices, reducing the need for premature replacements and minimizing electronic waste. In a time when electronic waste is a pressing global concern, Company X's eco-friendly approach is a step in the right direction, showcasing their commitment to corporate social responsibility.In line with their vision to revolutionize the electronic repair industry, Company X has also invested in advanced training and development programs for their technicians. This ensures that the team stays abreast of the latest technological advancements and repair techniques, enabling them to tackle even the most complex screen replacement challenges with ease. As a result, customers can have full confidence in the capabilities of Company X's technicians, knowing that their devices are in capable hands.Looking ahead, Company X has ambitious plans for expansion, aiming to reach more customers and establish a wider presence in the electronic repair market. With a growing demand for reliable and professional screen replacement services, the company is well-positioned to capitalize on this opportunity and make a positive impact on the industry. By continually raising the bar for excellence and innovation, Company X is laying the groundwork for a future where electronic repair is synonymous with quality, reliability, and sustainability.In conclusion, Company X's dedication to excellence, customer satisfaction, and environmental sustainability sets a new standard for the electronic repair industry. By offering top-notch screen replacement services and maintaining a customer-centric approach, the company has carved out a niche for itself as a trusted leader in the market. With a focus on continuous improvement and expansion, Company X is poised to shape the future of electronic repair, one screen replacement at a time.

Top-notch Shaker Screens for King Cobra Now Available - Latest News and Updates

Title: Cutting-Edge Shaker Screen Takes the Oil and Gas Industry by StormIntroduction[Company Name], a leading player in the oil and gas industry, has unveiled its latest innovation, the NOV Brandt King Cobra Shaker Screen. Designed to revolutionize the solids control and waste management process, this cutting-edge shaker screen promises to streamline drilling operations and enhance efficiency. By removing drilling solids and efficiently separating them from drilling fluid, this state-of-the-art technology aims to optimize the performance and lifespan of equipment, ultimately reducing costs and improving environmental sustainability. Let us delve deeper into the features and benefits of this remarkable product.Advanced Technology and Robust DesignThe NOV Brandt King Cobra Shaker Screen integrates advanced technology to deliver unparalleled performance in solids control. Incorporating a high-density technology mesh with a multi-layered design, this shaker screen ensures superior filtration capabilities, effectively removing unwanted particles and achieving particle size separation. The robust design ensures durability, enabling this screen to withstand the most demanding drilling conditions without compromising performance.Enhanced Efficiency and Cost ReductionEmploying the NOV Brandt King Cobra Shaker Screen in drilling operations brings forth several advantages that translate into enhanced efficiency and cost reduction. By effectively removing drilling solids, this screen prevents equipment from becoming clogged and greatly improves overall drilling fluid quality. The improved drilling fluid properties allow for increased drilling penetration rates, reducing downtime and boosting productivity. Additionally, with the elimination of unwanted solids in the drilling fluid, equipment lifespan is extended, leading to reduced maintenance costs and equipment replacement.By optimizing solids control, the NOV Brandt King Cobra Shaker Screen enables oil and gas companies to significantly minimize waste generation. The separation of drilling solids from the drilling fluid ensures that the recycled fluid can be reused efficiently, thereby reducing the need for freshly prepared drilling fluid. This not only cuts down on drilling fluid expenses but also contributes to environmental sustainability by lowering waste disposal requirements.Quality Control and ComplianceAs a trusted provider in the industry, [Company Name] ensures that the NOV Brandt King Cobra Shaker Screen adheres to the strictest quality control standards. The screen is designed to withstand rigorous testing and meets all industry specifications. Rigorous quality control measures are implemented throughout the manufacturing process to guarantee consistent performance and reliability.The NOV Brandt King Cobra Shaker Screen also complies with environmental regulations related to waste management in the oil and gas sector. By implementing this technology, companies can demonstrate their commitment to sustainable practices, preserving natural resources, and minimizing their ecological footprint.Global Reach and Market ImpactWith its innovative design and unmatched performance, the NOV Brandt King Cobra Shaker Screen has garnered significant attention and interest from oil and gas companies globally. [Company Name] has positioned itself as a global leader in providing efficient solids control solutions, empowering drilling operations worldwide. The company's dedication to innovation, customer-centric approach, and commitment to quality has propelled its products into the spotlight, securing its position as an industry frontrunner.ConclusionThe introduction of the NOV Brandt King Cobra Shaker Screen by [Company Name] signifies a breakthrough solution in solids control and waste management in the oil and gas industry. Its cutting-edge technology, robust design, and impressive performance set new standards for efficiency and cost reduction. By effectively removing drilling solids and optimizing drilling fluid quality, this shaker screen enhances overall equipment lifespan, productivity, and environmental sustainability. As the industry faces mounting challenges, [Company Name] continues to innovate and develop solutions that redefine the future of oil and gas operations.

High-Quality Shale Shaker Screen for Improved Efficiency and Performance

(Kemtron) Shale Shaker Screen Enhances Efficiency in Oil and Gas Drilling OperationsIn the fast-paced world of oil and gas drilling, efficiency and productivity are crucial. Every second counts, and any delays can result in significant financial losses. That's why companies are constantly on the lookout for innovative technology that can help streamline their operations and minimize downtime.One company that has been at the forefront of providing cutting-edge solutions for the oil and gas industry is {}. With a proven track record of delivering high-quality products and services, they have earned a reputation as a trusted partner for many drilling companies around the world.One of their flagship products, the (Kemtron) Shale Shaker Screen, has been making waves in the industry for its exceptional performance and reliability. This critical component plays a vital role in the drilling process, as it is responsible for separating drilling cuttings from the fluid, allowing for the recovery of valuable drilling fluid and minimizing waste.The (Kemtron) Shale Shaker Screen is designed to withstand the harsh conditions of drilling operations, including high temperatures, high pressure, and abrasive materials. Its durable construction and high-quality materials ensure that it can effectively withstand the demands of the job, leading to longer service life and reduced maintenance costs.In addition to its robust design, the (Kemtron) Shale Shaker Screen is also engineered for optimal performance. Its precise mesh size and efficient filtration capabilities allow for the effective removal of solid particles from the drilling fluid, resulting in cleaner fluid and improved drilling efficiency.Furthermore, the (Kemtron) Shale Shaker Screen is easy to install and maintain, minimizing downtime and maximizing productivity for drilling operations. Its user-friendly design and simple, straightforward maintenance requirements make it a practical choice for companies looking to enhance their overall operational efficiency.With the increasing demand for sustainable and environmentally friendly practices in the oil and gas industry, the (Kemtron) Shale Shaker Screen is also designed to contribute to these efforts. By effectively removing solid particles from the drilling fluid, it helps to reduce waste and minimize the environmental impact of drilling operations.As a leading provider of innovative solutions for the oil and gas industry, {} is committed to delivering products that not only improve operational efficiency but also align with the industry's evolving sustainability goals. The (Kemtron) Shale Shaker Screen is a testament to this commitment, as it offers a practical and effective solution for companies seeking to optimize their drilling operations while minimizing their environmental footprint.With its exceptional performance, durability, and environmental benefits, the (Kemtron) Shale Shaker Screen has quickly become a sought-after solution for many drilling companies. As the industry continues to evolve and demand more efficient and sustainable practices, it is clear that products like the (Kemtron) Shale Shaker Screen will play a crucial role in shaping the future of oil and gas drilling operations.In conclusion, the (Kemtron) Shale Shaker Screen is a valuable addition to the portfolio of innovative solutions offered by {}. Its exceptional performance, durability, and environmental benefits make it a practical choice for drilling companies seeking to enhance their operational efficiency and minimize their environmental impact. As the industry continues to evolve, solutions like the (Kemtron) Shale Shaker Screen will undoubtedly continue to be a driving force in shaping the future of oil and gas drilling operations.

High-Performance Shaker Screen for Swaco ALS-II - A Detailed Analysis

Swaco ALS-II shaker screen has emerged as a top solution for efficient solid control in the oil and gas industry. This high-performance shaker screen is designed to eliminate solids from drilling fluid and to ensure the smooth and efficient operation of the drilling equipment.The Swaco ALS-II shaker screen is equipped with advanced technology that enhances its performance and durability. The screen’s robust construction and fine mesh allow for effective separation of solid particles from drilling fluid, leading to improved drilling efficiency and reduced downtime. With its superior performance and long-lasting durability, the Swaco ALS-II shaker screen has become the preferred choice for many oil and gas companies around the world.The success of the Swaco ALS-II shaker screen can be attributed to the company behind its production. With a strong focus on research and development, the company has been able to consistently deliver innovative and high-quality products to the oil and gas industry. The company’s commitment to excellence and customer satisfaction has earned it a reputation as a leader in the field of solid control solutions.In addition to the Swaco ALS-II shaker screen, the company offers a comprehensive range of solid control equipment and services to meet the diverse needs of its clients. From shale shakers to centrifuges, the company’s product portfolio is designed to provide effective solutions for all stages of the drilling process. Moreover, the company’s team of highly skilled engineers and technicians are available to provide expert support and assistance to ensure the optimal performance of its equipment.The company’s dedication to quality and innovation is further underscored by its investment in state-of-the-art manufacturing facilities and strict quality control processes. This ensures that every product that bears the company’s name meets the highest standards of performance and reliability. As a result, the company has built a strong and loyal customer base that relies on its products and services for their solid control needs.Furthermore, the company places a strong emphasis on environmental sustainability and safety in all aspects of its operations. It adheres to strict environmental regulations and implements best practices to minimize the environmental impact of its products and services. Additionally, the company prioritizes the safety of its employees and clients by maintaining rigorous safety standards and investing in ongoing training and development programs.As a result of its continuous innovation, unwavering commitment to quality, and dedication to environmental sustainability and safety, the company has earned the trust and respect of the oil and gas industry. Its solid control products and services, including the Swaco ALS-II shaker screen, have become synonymous with reliability, efficiency, and cost-effectiveness.Looking ahead, the company remains focused on advancing its technologies and expanding its product offerings to meet the evolving needs of the oil and gas industry. With a strong track record of success and a passion for excellence, the company is well-positioned to continue leading the way in the field of solid control solutions.In conclusion, the Swaco ALS-II shaker screen, in combination with the company’s dedication to quality, innovation, environmental sustainability, and safety, has established itself as a top choice for efficient solid control in the oil and gas industry. With its superior performance and commitment to customer satisfaction, the company has earned its reputation as a trusted leader in the field.

Upgrade Your Shakers with New Generation Replacement Wave Screens for Enhanced Performance

Title: High-Quality Replacement Screens for Hyperpool Shakers Now AvailableIntroduction:In the ever-evolving world of oil and gas drilling, the search for advanced technologies and equipment that enhance efficiency and performance never ceases. The demand for reliable and durable shaker screens to optimize drilling operations has led to the development of cutting-edge replacement screens. One such offering is the recently launched Replacement Wave Screens, engineered specifically for Derrock Hyperpool Shakers, distributed by a leading industry player.Company Introduction:XYZ Drilling Solutions is a renowned company committed to providing innovative solutions to the oil and gas industry. With years of expertise and a strong track record of excellence, XYZ Drilling Solutions has established itself as a trusted partner for enhancing drilling efficiency and productivity.With a team of highly skilled professionals and a state-of-the-art manufacturing facility, XYZ Drilling Solutions strives to meet the ever-increasing demands of the global drilling market. Their commitment to quality and continuous improvement has earned them a reputation for delivering reliable and superior products.Replacement Wave Screens for Derrock Hyperpool Shakers:XYZ Drilling Solutions has recently unveiled their latest offering – Replacement Wave Screens for Derrock Hyperpool Shakers. These screens are designed to maximize the performance and efficiency of drilling operations, addressing the challenges faced by drilling professionals worldwide.The key features of the Replacement Wave Screens include:1. Superior Performance: The Replacement Wave Screens are engineered using advanced technology to provide exceptional solids control efficiency. The innovative design allows for better separation and increased throughput, resulting in improved drilling fluid recovery and reduced waste.2. Enhanced Durability: Made from top-quality materials that ensure longevity, the Replacement Wave Screens are built to withstand the harsh conditions encountered during drilling operations. Their robust construction minimizes the chance of premature failure, reducing downtime and maintenance costs.3. Optimized Conductance: The optimized design of the Wave Screens provides enhanced fluid conductance, allowing for efficient fluid flow while effectively retaining solids. This feature improves solids control, extends screen life, and reduces overall operating costs.4. Quick and Easy Installation: The Replacement Wave Screens are designed for hassle-free installation, ensuring minimal downtime during screen changeouts. The screens can seamlessly fit onto Derrock Hyperpool Shakers, making them a convenient and reliable choice for drilling professionals.5. Compatibility: XYZ Drilling Solutions' Replacement Wave Screens are exclusively engineered to fit Derrock Hyperpool Shakers. This compatibility ensures a perfect fit, maintaining the integrity of the shaker and optimizing the overall performance."XYZ Drilling Solutions is proud to introduce our Replacement Wave Screens for Derrock Hyperpool Shakers," said John Doe, CEO of XYZ Drilling Solutions. "We have relished the opportunity to work closely with drilling professionals to develop a high-quality screen that addresses their specific needs. Our team has invested significant time and expertise to ensure that our screens maximize drilling efficiency and reduce overall operational costs."With a commitment to providing exceptional customer service, XYZ Drilling Solutions offers comprehensive technical support and guidance to assist clients in selecting the right Replacement Wave Screens for their operations. The company's extensive network of distribution centers ensures prompt and reliable delivery to customers worldwide.Conclusion:With the introduction of XYZ Drilling Solutions' Replacement Wave Screens exclusively designed for Derrock Hyperpool Shakers, the industry can embrace a new level of drilling efficiency and performance. The advanced technology employed in these screens ensures superior performance, enhanced durability, and easy installation. XYZ Drilling Solutions continues to set industry standards and reaffirms its dedication to providing innovative solutions to the global oil and gas drilling industry.

Industry News: Upgraded Shale Shaker Screens for Efficient Solids Control on S250 Shakers

Shale Shaker Screen for S250: The New Breakthrough in Oil and Gas Drilling IndustryThe oil and gas drilling industry has been facing increasing pressure to improve its operational efficiency as the oil prices continue to fluctuate. With the need to maximize production and minimize costs, operators are consistently seeking new technology to improve the drilling process. One of the biggest challenges in the drilling industry is the proper handling of drilled cuttings and mud away from the borehole. This is where the shale shaker screen comes in.A shale shaker screen is an essential component of drilling equipment that is used to screen the drilling fluid and cuttings from the borehole. The shale shaker screen is designed to handle a high capacity of solids to ensure that the drilling fluid is well controlled and to extend the life of the drilling equipment through efficient solids removal. A new technology, the shale shaker screen for S250, has been developed to solve the problem of inefficient solids control during drilling operations.The S250 shale shaker screen is a breakthrough technology in the oil and gas industry. It is designed to replace the conventional screens and improve the shale shaker's performance with its advanced capabilities. The shale shaker screen for S250 is manufactured using advanced techniques to ensure its durability and longevity. It is made from high-quality stainless steel mesh, ensuring its resistance to wear and tear, and it has been tested under the harshest drilling conditions to ensure its efficiency in dealing with high-speed cuttings.The shale shaker screen for S250 provides significant operational and financial benefits. With its high-capacity performance, it reduces the overall cost of drilling operations by reducing the number of screens required for the operation. The shale shaker screen for S250 is also easy to install and replace, reducing the downtime of the drilling operation, which results in higher efficiency and faster drilling times.The company behind the development of the S250 shale shaker screen has a reputation for excellence. The company has been providing cutting-edge technology solutions for drilling, exploration, and production operations for more than a decade. Its mission is to provide customized solutions that optimize operational efficiency in the oil and gas industry. The S250 shale shaker screen is a testament to the company's commitment to providing innovative solutions that meet the needs of the industry.In conclusion, the shale shaker screen for S250 is a game-changer in the drilling industry. It is designed to improve the efficiency of the drilling operation by providing a high-capacity, durable and efficient solution for solids removal. Its advanced capabilities result in reduced screen usage and faster drilling times, leading to significant operational and financial benefits. The company behind the development of the S250 shale shaker screen is dedicated to delivering innovative technology solutions that help the drilling industry achieve peak performance. The future of the drilling industry is bright with advancements like the shale shaker screen for S250, and the industry can expect even more breakthroughs in the years to come as we continue to push the limits of innovation.

Top Features of the New S250 Screen Revealed in Latest News Report

In today's fast-paced and technology-driven world, the demand for high-quality screens has never been greater. As an industry leader in screen manufacturing, {} has once again raised the bar with the introduction of the S250 Screen. This cutting-edge product is revolutionizing the way we experience visuals and setting a new standard for screen performance.The S250 Screen is the result of years of research, development, and innovation. {}'s team of experts have worked tirelessly to create a screen that not only meets but exceeds the expectations of today's consumers. The result is a product that delivers unparalleled image clarity, color accuracy, and overall picture quality.One of the standout features of the S250 Screen is its advanced display technology. With a high resolution and pixel density, this screen ensures that every image is rendered with stunning detail and precision. Whether it's watching a movie, playing video games, or working on graphic design projects, the S250 Screen provides a level of visual fidelity that is unmatched in the industry.In addition to its impressive display capabilities, the S250 Screen also boasts a number of other attractive features. For example, it incorporates state-of-the-art anti-glare technology that reduces reflections and improves visibility in bright environments. This makes it ideal for use in a wide range of settings, from living rooms to office spaces and beyond.Furthermore, the S250 Screen is designed with user convenience in mind. Its sleek and slim profile makes it easy to integrate into any environment, while its intuitive interface and controls ensure a user-friendly experience for all consumers. Whether it's mounting the screen on a wall or placing it on a stand, the S250 Screen offers flexibility and versatility to meet the needs of any user.In terms of connectivity, the S250 Screen offers a variety of options to ensure seamless integration with other devices. It features multiple HDMI inputs, USB ports, and wireless capabilities, allowing users to easily connect their favorite devices, such as laptops, gaming consoles, and streaming media players.The durability of the S250 Screen is also worth noting. Constructed with high-quality materials and built to withstand the rigors of daily use, this screen is designed to provide years of reliable performance. Its long lifespan and low maintenance requirements make it a cost-effective investment for both consumers and businesses.In summary, the S250 Screen represents a new pinnacle of screen technology. With its stunning visual performance, advanced features, and user-friendly design, it is sure to become the go-to choice for anyone in need of a high-quality screen. As {} continues to push the boundaries of innovation, the S250 Screen stands as a testament to their commitment to excellence and their dedication to providing consumers with the best possible products. Whether it's for entertainment, productivity, or any other application, the S250 Screen is poised to elevate the viewing experience to new heights.