| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Non-Blank Area (sq.ft) |

|---|---|---|---|---|---|

| KET-KC/Hybrid-A325 | XR/XL | API 325 | 0.33 | 44 | 5.95 |

| KET-KC/Hybrid-A270 | XR/XL | API 270 | 0.42 | 54 | 5.95 |

| KET-KC/Hybrid-A230 | XR/XL | API 230 | 0.45 | 61 | 5.95 |

| KET-KC/Hybrid-A200 | XR/XL | API 200 | 0.62 | 72 | 5.95 |

| KET-KC/Hybrid-A170 | XR/XL | API 170 | 1.02 | 86 | 5.95 |

| KET-KC/Hybrid-A140 | XR/XL | API 140 | 1.03 | 106 | 5.95 |

| KET-KC/Hybrid-A120 | XR/XL | API 120 | 1.40 | 134 | 5.95 |

| KET-KC/Hybrid-A100 | XR/XL | API 100 | 1.67 | 159 | 5.95 |

| KET-KC/Hybrid-A80 | XR/XL | API 80 | 2.36 | 193 | 5.95 |

| KET-KC/Hybrid-A70 | XR/XL | API 70 | 2.78 | 230 | 5.95 |

| KET-KC/Hybrid-A60 | XR/XL | API 60 | 3.35 | 274 | 5.95 |

| KET-KC/Hybrid-A50 | XL | API 50 | 4.91 | 296 | 5.95 |

| KET-KC/Hybrid-A35 | XL | API 35 | 9.13 | 529 | 5.95 |

| KET-KC/Hybrid-A20 | XL | API 20 | 11.77 | 781 | 5.95 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | |||||

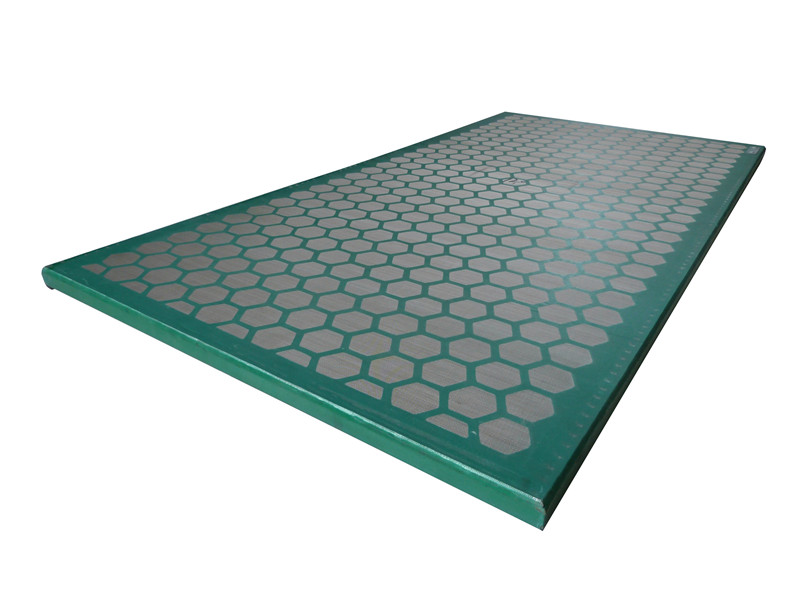

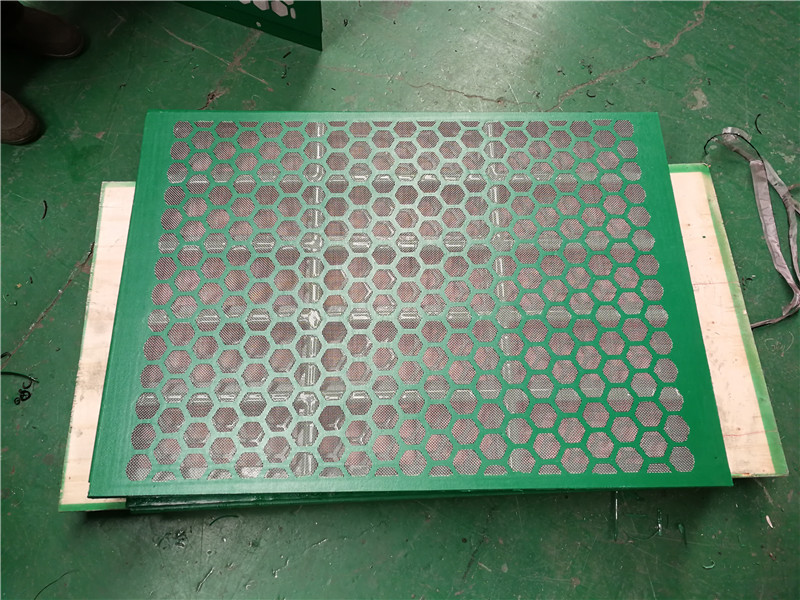

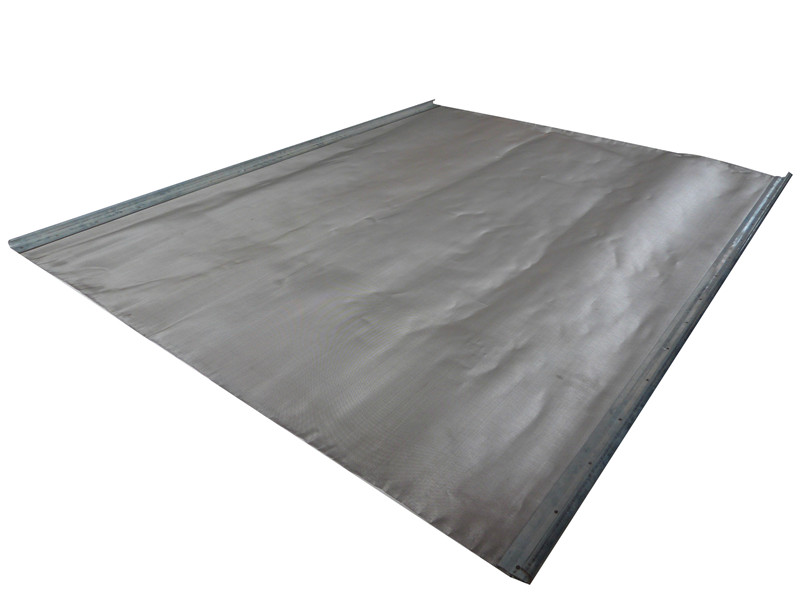

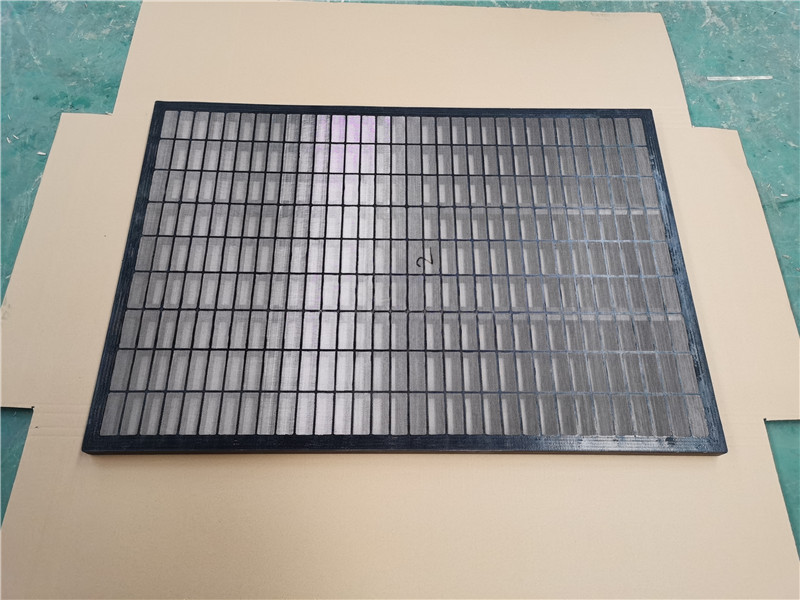

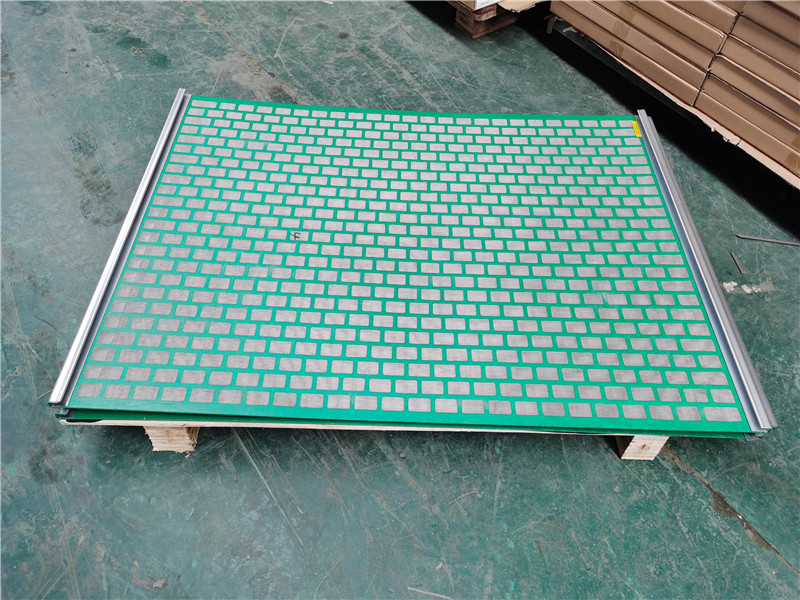

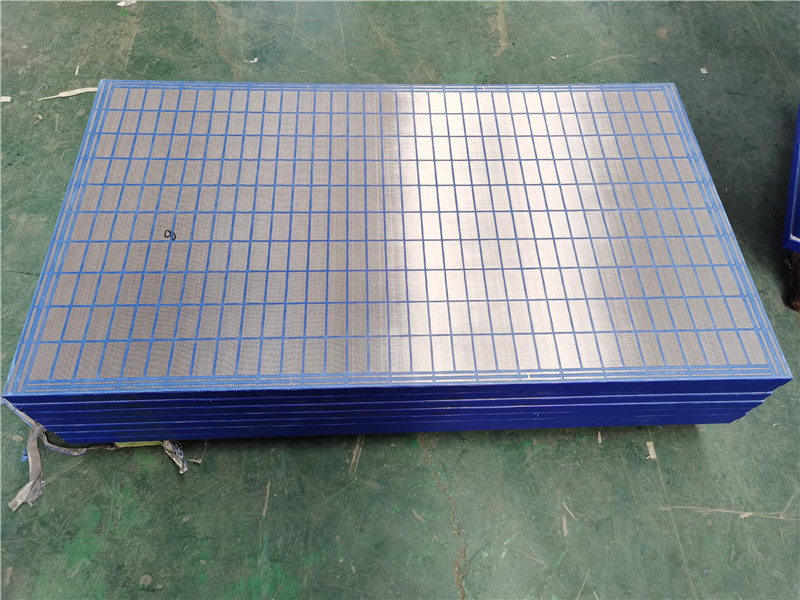

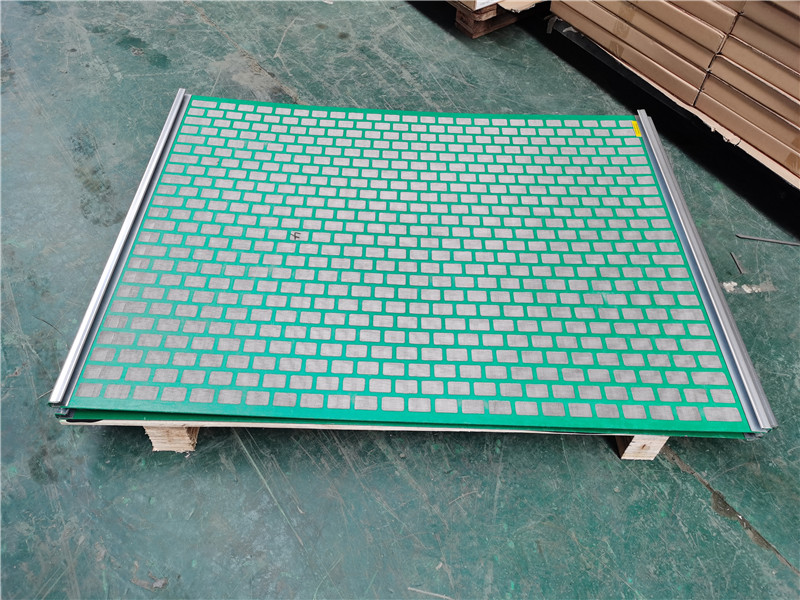

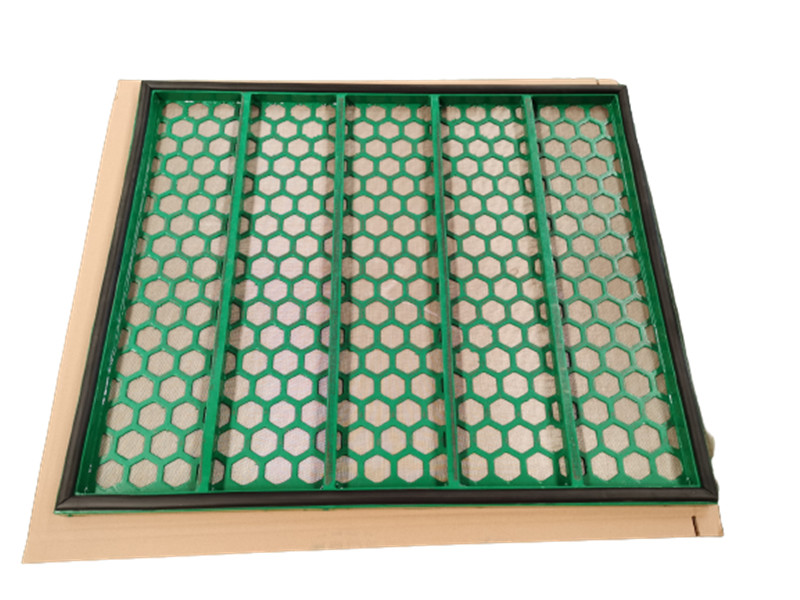

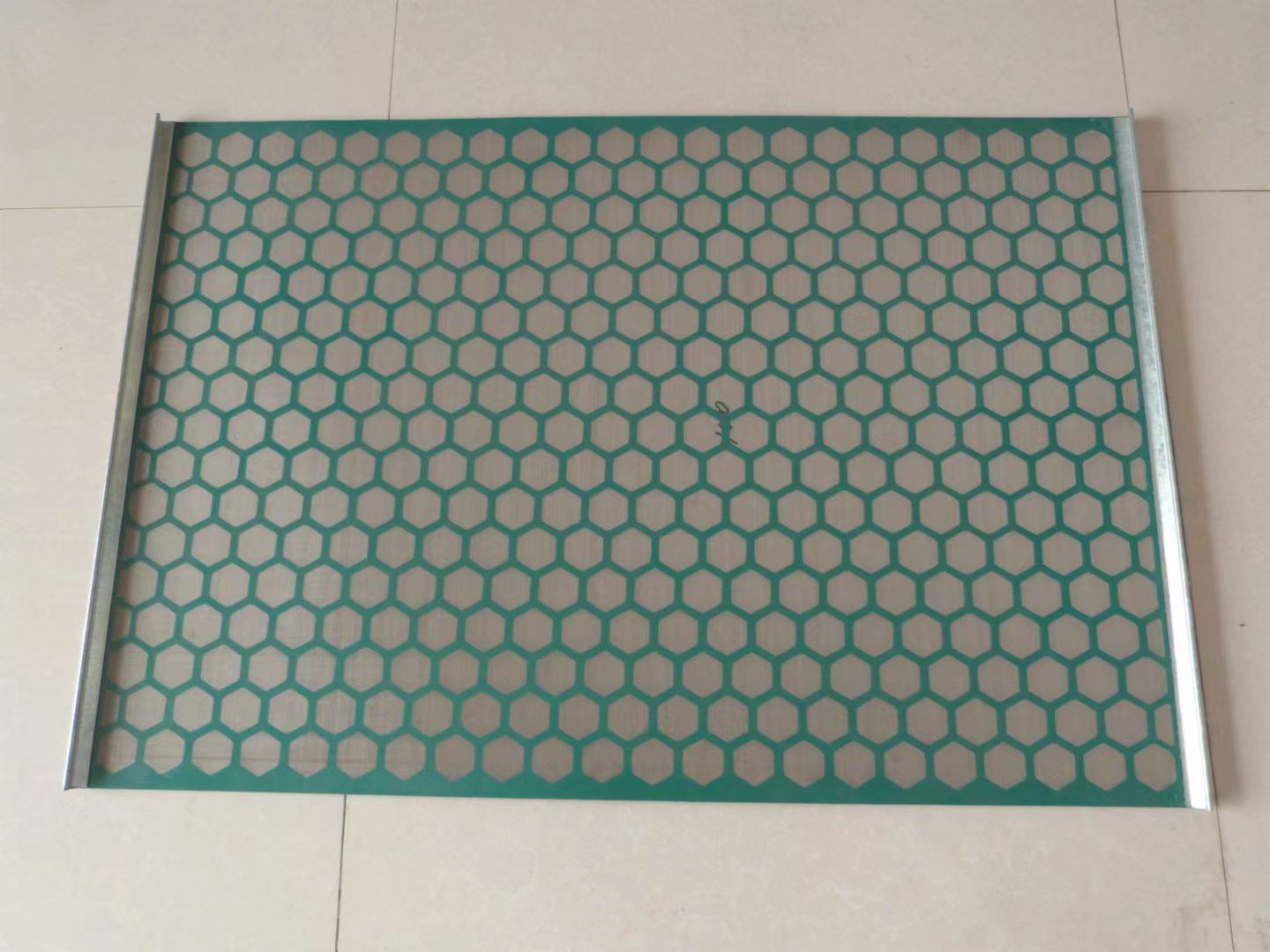

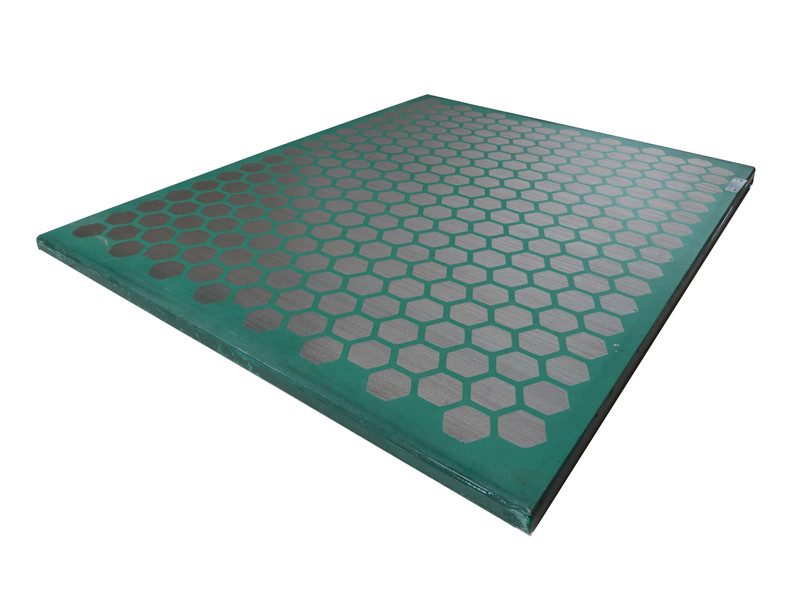

Replacement Screen for Brandt King CobraHybridVenom

Get high-quality replacement screens for Brandt King CobraHybridVenom. We are a trusted factory offering reliable solutions to meet your needs. Shop now!

Request a QuotePRODUCTS DETAILS

Hot Products

Replacement Screen for VSM 100

Brandt VSM Multi-sizer Scapling

Replacement Screen for Brandt 4 × 5 B40

Replacement Screen for FSI 5000

Replacement Screen for Brandt BLT-50LCM-2D

Replacement Screen for KEMTRON 28

Replacement Screen for BEM-3 PWP

Replacement Screen for GNZS-752

Replacement Screens for Derrock FLC 2000 / 48 × 30 Shale Shakers – PWP

Brandt VSM 300 Primary

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours