Discover the Latest Innovations: Unveiling the New Generation of Vibrating Screens

By:Admin

[Date]

[Location]

[News Content]:

In the constantly evolving landscape of industrial machinery, a breakthrough invention has recently emerged to revolutionize the way materials are sieved and distinguished. An innovative Vibrating Screen, developed by a pioneering company [], is set to transform various industries by offering enhanced efficiency and heightened productivity.

In today's fast-paced world, efficiency and productivity are key factors determining the success of any business. Recognizing this, [] has focused its efforts on reimagining the conventional vibrating screen and introducing cutting-edge features that streamline operations and yield remarkable results. While the brand name has been removed for confidentiality reasons, its reputation as an industry leader precedes it.

The redesigned Vibrating Screen incorporates state-of-the-art technology and key advancements to cater to the specific needs of the industries it serves. With its improved design, it ensures optimal screening of materials, reducing the possibility of clogs or blockages. This allows for a seamless flow of materials, boosting productivity and minimizing downtime, leading to substantial cost savings for businesses.

One of the standout features of this Vibrating Screen is its high-frequency vibration capabilities. Unlike traditional screens, this new technology enables precise particle separation, guaranteeing superior accuracy and consistency. This means that materials can be efficiently classified into desired sizes, removing any impurities or foreign objects. The result is a higher quality end-product that meets the stringent standards of various industries, including mining, construction, and agriculture.

The screen is built using high-quality, durable materials, ensuring longevity and reliability even under challenging operating conditions. Additionally, it is designed with ease of maintenance in mind, featuring quick-release mechanisms that facilitate convenient cleaning and screen replacement. This not only saves precious time but also enhances operational efficiency, allowing businesses to focus on core activities and maximize output.

Beyond its technical excellence, [] is committed to sustainable practices. The Vibrating Screen operates with minimal energy consumption, aligning with the company's environmental stewardship objectives. By opting for this innovative solution, businesses can contribute to reducing their carbon footprint, while also benefiting from reduced energy costs.

To further cater to the diverse needs of its customers, [] provides customization options for the Vibrating Screen. This ensures seamless integration into existing production lines, facilitating a smooth transition without disrupting ongoing operations. The company's team of experienced engineers work closely with clients to understand their specific requirements, ensuring a tailored solution that meets their unique industry demands.

The launch of this revolutionary Vibrating Screen by [] marks a significant milestone in the industrial machinery sector. Its advanced features, combined with the company's commitment to excellence and sustainable practices, position it as a front-runner in the market. With its exceptional efficiency, productivity, and long-term reliability, this innovation is set to reshape the industry and empower businesses to thrive in a rapidly changing world.

[Company Introduction]:

[] is a renowned industry leader dedicated to providing innovative solutions for various industrial sectors. With a strong focus on research and development, the company has consistently pushed the boundaries of technological advancements to address the evolving needs of its customers. Their team of experts combines expertise with a passion for excellence, ensuring the delivery of exceptional products that drive efficiency and productivity.

Combining cutting-edge technologies, engineering excellence, and a customer-centric approach, [] has won the trust of a wide range of industries worldwide. With a diverse portfolio of industrial machinery, the company continues to be at the forefront of innovation, enabling businesses to stay competitive in today's challenging market.

For more information about [], its revolutionary Vibrating Screen, and other transformative solutions, please visit [website] or contact [contact details].

###

[Word Count: 800 words]

Company News & Blog

Latest Innovation in Vibrating Screens: Xxnx Powder Screening Solution

Title: State-of-the-Art Powder Vibrating Screen Revolutionizes Industrial ProcessesIntroduction:In the ever-evolving world of industrial technology, innovation plays a crucial role in optimizing productivity and improving efficiency. The renowned industrial machinery manufacturer, {Company Name}, takes this concept to new heights with its cutting-edge powder vibrating screen. This state-of-the-art device revolutionizes the handling of powders, offering a solution that enhances production processes across various industries.Section 1: The Need for Advanced Powder Vibrating ScreensPowders are widely used in multiple sectors, including pharmaceuticals, chemicals, food processing, and more. However, conventional methods of handling and screening powders often present several challenges. These include inefficient separation, limited capacity, and increased maintenance requirements, leading to higher costs and reduced overall productivity. Recognizing this need for improvement, {Company Name} engineered a solution that addresses these issues head-on.Section 2: Key Features and BenefitsThe {Company Name} powder vibrating screen is equipped with an array of cutting-edge features that ensure superior performance and reliability. The following are the paramount benefits offered by this innovative technology:1. Enhanced Separation Efficiency: The vibrating screen's advanced design and state-of-the-art components enable exceptional separation efficiency, ensuring optimized product quality and minimized wastage. The precision engineering of the screen effectively removes impurities and particles of different sizes, resulting in a refined end product.2. Increased Capacity: The increased capacity of the {Company Name} powder vibrating screen allows for higher throughput, enabling industries to meet growing demands efficiently. This improved productivity leads to enhanced overall production rates and ultimately boosts profitability.3. Easy Maintenance: {Company Name} has prioritized user-friendliness when designing this vibrating screen. The streamlined structure and easily accessible components simplify maintenance tasks, reducing downtime and minimizing production interruptions. This feature enables businesses to operate smoothly and maximize uptime.4. Flexible Design Options: Recognizing the diverse needs of industries, {Company Name} offers customization options for its powder vibrating screen. This flexibility allows businesses to tailor the device to their specific requirements, enhancing its compatibility with existing production lines.Section 3: Industry ApplicationsThe versatility of the {Company Name} powder vibrating screen makes it applicable across a wide range of industries. Key sectors that can benefit from this technology include:1. Pharmaceutical Industry: The precision separation capabilities of the vibrating screen make it ideal for pharmaceutical companies needing to screen active pharmaceutical ingredients (APIs) and medicinal powders. The efficient separation ensures product consistency and quality control.2. Chemical Industry: Chemical producers can improve their handling of different powder compounds, including pigments, dyes, and additives, by utilizing this advanced vibrating screen. It enhances separation precision, avoiding cross-contamination issues and enhancing productivity.3. Food Processing Industry: In the food processing sector, the powder vibrating screen offers an efficient solution for ingredients such as flour, sugar, spices, and additives. The device ensures product uniformity and purity, meeting stringent quality standards in food production.Section 4: Customer Testimonials{Company Name} has garnered positive feedback from its customers who have experienced the benefits of the powder vibrating screen firsthand. Renowned industries across various sectors have reported substantial improvements in their production processes, emphasizing increased efficiency, reduced downtime, and enhanced product quality.Conclusion:The revolutionary powder vibrating screen by {Company Name} is a game-changer in the industrial machinery market. Its advanced features, coupled with customizable options, offer businesses the opportunity to streamline their powder handling and ensure optimum production rates. With its wide-ranging applications across diverse industries, the vibrating screen supports businesses in achieving higher productivity, improved product quality, and increased profitability. The continued commitment of {Company Name} to innovation sets them apart as a trusted partner in the industrial machinery sector.

Discover the Latest Innovations: Unveiling the New Generation of Vibrating Screens

[News Title]: Innovative Vibrating Screen Revolutionizes the Industry, Offering Enhanced Efficiency and Productivity[Date][Location][News Content]:In the constantly evolving landscape of industrial machinery, a breakthrough invention has recently emerged to revolutionize the way materials are sieved and distinguished. An innovative Vibrating Screen, developed by a pioneering company [], is set to transform various industries by offering enhanced efficiency and heightened productivity.In today's fast-paced world, efficiency and productivity are key factors determining the success of any business. Recognizing this, [] has focused its efforts on reimagining the conventional vibrating screen and introducing cutting-edge features that streamline operations and yield remarkable results. While the brand name has been removed for confidentiality reasons, its reputation as an industry leader precedes it.The redesigned Vibrating Screen incorporates state-of-the-art technology and key advancements to cater to the specific needs of the industries it serves. With its improved design, it ensures optimal screening of materials, reducing the possibility of clogs or blockages. This allows for a seamless flow of materials, boosting productivity and minimizing downtime, leading to substantial cost savings for businesses.One of the standout features of this Vibrating Screen is its high-frequency vibration capabilities. Unlike traditional screens, this new technology enables precise particle separation, guaranteeing superior accuracy and consistency. This means that materials can be efficiently classified into desired sizes, removing any impurities or foreign objects. The result is a higher quality end-product that meets the stringent standards of various industries, including mining, construction, and agriculture.The screen is built using high-quality, durable materials, ensuring longevity and reliability even under challenging operating conditions. Additionally, it is designed with ease of maintenance in mind, featuring quick-release mechanisms that facilitate convenient cleaning and screen replacement. This not only saves precious time but also enhances operational efficiency, allowing businesses to focus on core activities and maximize output.Beyond its technical excellence, [] is committed to sustainable practices. The Vibrating Screen operates with minimal energy consumption, aligning with the company's environmental stewardship objectives. By opting for this innovative solution, businesses can contribute to reducing their carbon footprint, while also benefiting from reduced energy costs.To further cater to the diverse needs of its customers, [] provides customization options for the Vibrating Screen. This ensures seamless integration into existing production lines, facilitating a smooth transition without disrupting ongoing operations. The company's team of experienced engineers work closely with clients to understand their specific requirements, ensuring a tailored solution that meets their unique industry demands.The launch of this revolutionary Vibrating Screen by [] marks a significant milestone in the industrial machinery sector. Its advanced features, combined with the company's commitment to excellence and sustainable practices, position it as a front-runner in the market. With its exceptional efficiency, productivity, and long-term reliability, this innovation is set to reshape the industry and empower businesses to thrive in a rapidly changing world.[Company Introduction]:[] is a renowned industry leader dedicated to providing innovative solutions for various industrial sectors. With a strong focus on research and development, the company has consistently pushed the boundaries of technological advancements to address the evolving needs of its customers. Their team of experts combines expertise with a passion for excellence, ensuring the delivery of exceptional products that drive efficiency and productivity.Combining cutting-edge technologies, engineering excellence, and a customer-centric approach, [] has won the trust of a wide range of industries worldwide. With a diverse portfolio of industrial machinery, the company continues to be at the forefront of innovation, enabling businesses to stay competitive in today's challenging market.For more information about [], its revolutionary Vibrating Screen, and other transformative solutions, please visit [website] or contact [contact details].###[Word Count: 800 words]

Top Primary Screens for the NOV VSM300: Enhancing Efficiency and Performance

release for an oil drilling companyIn the oil drilling industry, having reliable and efficient equipment is crucial in ensuring the success of a drilling operation. One of the most important equipment in this business is the drilling screening system. XYZ Oil Drilling Company understands the importance of having top-of-the-line drilling screening systems that can withstand and operate under the harshest conditions. That is why the company is proud to announce an addition to its equipment line-up- the NOV VSM300 Primary Screen.The NOV VSM300 Primary Screen is meticulously designed and manufactured by National Oilwell Varco (NOV), one of the leading providers of innovative drilling solutions in the world. The NOV VSM300 is recognized in the industry for its efficiency, reliability, and durability, making it the perfect fit to handle the challenging drilling operations that XYZ Oil Drilling Company is known for.The primary screen features a two-bearing design that provides higher throughput, lower maintenance costs, and increased screen life compared to traditional screening systems. Its advanced design has also eliminated several previous challenges related to vibration and noise, making it one of the most sought-after screening systems in the industry.One of the NOV VSM300's key features is its ability to operate with a wide range of drilling fluids, including synthetic-based, oil-based, and water-based. This versatility allows it to handle varying drilling conditions, making it ideal for the needs of the XYZ Oil Drilling Company.The primary screen's mesh size is customizable and can consist of single, double, or even triple-layer configurations to help improve filtration efficiency. The design of the NOV VSM300 Primary Screen also provides for increased energy efficiency, which helps lower operating costs. In addition, the system is built with ease of use in mind and can be installed and maintained quickly, maximizing uptime and productivity.Speaking on the addition of the NOV VSM300 Primary Screen to their equipment lineup, a spokesperson from XYZ Oil Drilling Company said, "At XYZ Oil Drilling, we are committed to providing our clients with the best drilling equipment available. The addition of the NOV VSM300 Primary Screen is part of our ongoing commitment to improve our operations continually. We are thrilled to partner with NOV to bring our clients a new level of productivity and efficiency."The NOV VSM300 Primary Screen is just one of the many top-of-the-line products that XYZ Oil Drilling Company offers its clients. The company provides a comprehensive range of oil drilling services, including drilling, completions, production, and well intervention. It boasts a fleet of modern drilling rigs and highly trained personnel who can operate in all types of drilling environments, making it the go-to company for oil drilling needs.Overall, the addition of the NOV VSM300 Primary Screen by XYZ Oil Drilling Company is a testament to its commitment to providing its clients with the best equipment available. The partnership with NOV has not only raised the bar for drilling screening systems, but it will also improve the company's services, ensuring they remain at the forefront of the oil drilling industry. In conclusion, the NOV VSM300 Primary Screen will play a vital role in ensuring the success of drilling operations for XYZ Oil Drilling Company and its clients. With its advanced features and capabilities, it is a valuable investment that will result in faster, more efficient, and safer drilling operations.

Efficient Replacement Shaker Screens for Mongoose Models – Get Unmatched Performance

Title: Industry-Leading Shaker Screens by Mi-Swaco Revolutionize Solids Control SystemsIntroduction (85 words):Solids control technology plays a vital role in the efficient and cost-effective drilling of oil and gas wells. In this regard, Mi-Swaco, an industry-leading provider of innovative solutions, has recently unveiled their latest shaker screens designed to deliver unparalleled performance in solids control. With a commitment to continually revolutionize drilling operations, Mi-Swaco's technologically advanced shaker screens are set to enhance operational efficiency while reducing downtime and maintenance costs.Section 1: The Significance of Solids Control in Drilling Operations (150 words)Efficient solids control is crucial during the drilling process, as it helps to remove drill cuttings and other solid particles from drilling mud, ensuring its integrity and functionality. Effective solids control systems prevent drill bits from becoming excessively worn or damaged, optimize drilling performance, and protect downstream equipment. By adopting cutting-edge technologies and innovative designs, Mi-Swaco has emerged as a leading provider of solids control solutions that improve drilling operations across the industry.Section 2: The Pioneering Technology Behind Mi-Swaco's Shaker Screens (180 words)Mi-Swaco's latest breakthrough comes in the form of their technologically advanced shaker screens. These screens incorporate state-of-the-art materials and unique design features that maximize separation efficiency while extending their operational lifespan. The brand has engineered these screens using an innovative composite frame that enhances durability, resists corrosion, and prolongs screen performance.Moreover, Mi-Swaco's shaker screens utilize a specialized mesh configuration, featuring precise wire weaves, to achieve optimal filtration accuracy. This advanced technology ensures superior solids removal and improved fluid handling, guaranteeing an optimized drilling process. The screens' hassle-free installation and maintenance procedures further enhance their appeal, reducing downtime and increasing overall operational efficiency.Section 3: Mi-Swaco's Commitment to Continuous Innovation (130 words)Mi-Swaco has a robust track record of innovation in the drilling industry, driven by a commitment to enhancing solids control systems. Their team of experts consistently pushes the boundaries of technology to develop products that address specific industry challenges. With extensive research and development efforts, they continue to refine and optimize their shaker screens, aiming to make them the gold standard in the industry.Section 4: Operational and Economic Benefits of Mi-Swaco Shaker Screens (180 words)The implementation of Mi-Swaco's shaker screens provides a range of operational and cost benefits. By effectively separating solids from drilling mud, the screens improve drilling fluid properties, thereby increasing drilling efficiency and reducing the risk of equipment failure. Improved separation efficiency translates to reduced mud consumption and less waste disposal, resulting in significant cost savings for drilling operators.Additionally, the durability and extended lifespan of Mi-Swaco's shaker screens contribute to economies of scale. Reduced screen replacement frequency and minimal maintenance requirements lead to decreased downtime, ensuring uninterrupted drilling operations. This increased uptime, combined with the screens' innovative design features, ultimately leads to substantial cost savings over the long term.Conclusion (75 words):Mi-Swaco's innovative shaker screens are set to revolutionize solids control systems in the drilling industry. With their commitment to continuous improvement and cutting-edge technology, Mi-Swaco has developed a range of shaker screens that deliver superior performance, increased operational efficiency, and significant cost savings for drilling operators. By utilizing these advanced screens, drilling companies can optimize solids control, enhance drilling productivity, and ultimately drive success in the oil and gas industry.

Innovative Flat Oil Shaker Screen for Improved Drilling Performance

Title: Revolutionary Oil Shaker Screen Sets New Standard in Drilling IndustryIntroduction:In the ever-evolving oil and gas industry, technological advancements continue to shape the way drilling operations are conducted. One such breakthrough is the Duraflo D500 Flat Oil Shaker Screen, a cutting-edge solution that has quickly made its mark as a game-changer in the industry. Developed by a leading manufacturer [], this innovative screen has earned a reputation for its unmatched efficiency and performance, revolutionizing drilling processes worldwide.1. Meeting the Demands of a Changing Industry:With increasing demands for efficient drilling practices, the Duraflo D500 Flat Oil Shaker Screen has emerged as an industry leader. Its advanced design incorporates state-of-the-art technologies that not only improve efficiency but also reduce downtime, consequently enhancing overall productivity. This product addresses the challenges faced by drillers globally, offering a versatile and efficient solution that outperforms its competitors.2. Advanced Design for Enhanced Performance:The Duraflo D500 Flat Oil Shaker Screen showcases a meticulously engineered design that optimizes operational efficiency. By leveraging modern materials and innovative construction techniques, this screen effectively tackles the issues of wear and tear, thereby extending its lifespan and reducing maintenance costs. Its flat surface and precise mesh size ensure maximum cuttings recovery and improved solids control, resulting in enhanced mud handling capabilities during drilling operations.3. Unmatched Durability and Longevity:Durability is a key factor in the oil and gas industry, where equipment must withstand harsh operating conditions. The Duraflo D500 Flat Oil Shaker Screen excels in this aspect, offering exceptional resistance against abrasive materials and corrosive fluids encountered during drilling operations. The screen's materials are specifically chosen for their ruggedness and ability to withstand intense pressure, providing long-lasting performance and reducing the need for frequent replacements.4. Customization for Optimal Performance:Recognizing the diverse needs of the drilling industry, [], the manufacturer of the Duraflo D500 Flat Oil Shaker Screen, offers customization options to meet specific requirements. By tailoring the screen to match unique drilling conditions, customers can achieve optimal performance and maximize efficiency. With a wide range of sizes and configurations available, drillers can seamlessly integrate the screen into their operations, resulting in improved overall output.5. Environmental Benefits:In addition to its operational advantages, the Duraflo D500 Flat Oil Shaker Screen offers environmental benefits. Its efficient solids control capabilities aid in reducing the amount of waste generated during drilling operations. By effectively separating cuttings and solids from the drilling mud, this screen minimizes the environmental impact associated with disposal and promotes responsible waste management practices.6. Global Adoption and Recognition:The Duraflo D500 Flat Oil Shaker Screen has gained widespread recognition and global adoption within the drilling community. Its outstanding performance has led to increased productivity and cost savings for drilling companies worldwide. Collaborating with industry leaders and continuously improving their products, [], the manufacturer has successfully established themselves as a reliable provider of next-generation drilling solutions.Conclusion:As the oil and gas industry continues to evolve, the demand for effective equipment solutions has never been greater. The Duraflo D500 Flat Oil Shaker Screen has emerged as a revolutionary product, setting new standards for efficiency, durability, and environmental sustainability. With its advanced design, customized options, and recognized performance, this screen proves to be a vital asset for drillers seeking enhanced productivity and cost savings. As technology advances, the Duraflo D500 Flat Oil Shaker Screen showcases how innovation can revolutionize the drilling industry, paving the way for more efficient and sustainable practices.

How to Clean a Lint Trap: A Step-By-Step Guide for Your Dryer

Title: Innovative Dryer Screen Revolutionizes Laundry ExperienceIntroduction (100 words):The laundry industry is witnessing a groundbreaking innovation with the introduction of an advanced dryer screen that promises to enhance the efficiency and convenience of laundry operations. Developed by a prominent company, this ingenious device is poised to transform the way we approach laundry, offering benefits such as increased drying speed, reduced energy consumption, and improved fabric care. With features specifically designed to meet the evolving demands of modern households, this dryer screen aims to streamline the drying process for consumers. Let's delve deeper into the functionality and advantages of this pioneering appliance.[Image: An eye-catching image showcasing the advanced dryer screen in action]Part 1: Advanced Dryer Screen - A Game-Changer in Laundry (300 words)In today's fast-paced world, time-saving solutions are always appreciated. The advanced dryer screen, developed by the renowned company, has arrived as the ultimate game-changer in the laundry arena. Traditional drying methods can be tedious, time-consuming, and energy-draining. However, this new appliance aims to revolutionize these challenges by offering unmatched performance and efficiency.One of the key features of this dryer screen is its cutting-edge technology that dramatically reduces the drying time. Through a combination of increased air circulation and optimized heat distribution, this gadget ensures clothes are dried faster than ever before. This means users can enjoy significant time savings and have their freshly laundered garments ready to wear in no time.Moreover, this revolutionary dryer screen is designed to be eco-friendly. By utilizing intelligent sensors and advanced programming, it optimizes the energy consumption during the drying cycle. This not only helps in reducing utility bills but also contributes to a greener planet by minimizing energy waste. The device's sensor technology automatically adjusts the drying time and temperature based on the moisture levels, ensuring garments are dried efficiently without overdrying or damaging delicate fabrics.Part 2: Unparalleled Convenience and Customization (300 words)In addition to its incredible drying capabilities, this dryer screen offers a range of convenient features that make laundry chores a breeze. The device is equipped with a user-friendly interface, allowing users to easily select different drying options based on their fabric types, desired dryness levels, and sensory preferences. Whether it's a delicate load or a bulky load, this appliance offers various customizable settings to ensure optimum drying results.Furthermore, the advanced dryer screen incorporates smart connectivity features. Through a dedicated mobile app, users can remotely monitor and control the drying process. This means they can start, pause, or adjust the drying cycle from the comfort of their couch or while on the go. The app also provides timely notifications, alerting users when the drying cycle is complete, eliminating the need for constant monitoring.Additionally, this state-of-the-art appliance includes a range of safety features, ensuring peace of mind for users. These safety mechanisms include automatic shut-off in the event of overheating, a lint trap indicator to prevent clogging, and built-in sensors to detect irregularities or malfunctions.Part 3: Future Prospects and Conclusion (200 words)The introduction of this innovative dryer screen marks a significant milestone in the laundry industry. With its extensive features, advanced technology, and commitment to sustainability, it is expected to redefine the realm of laundry appliances. The company's dedication to research and development, along with a focus on customer needs, has resulted in a product that promises to make laundry routines more efficient, while also prioritizing fabric care and energy conservation.As this pioneering appliance garners attention and accolades, consumers can anticipate a more seamless and enjoyable laundry experience. The future prospects of this innovative dryer screen seem promising, and it is likely that similar developments will emerge to further revolutionize the laundry market. With the introduction of this advanced device, the days of tedious laundry routines may soon become a thing of the past.[Note: Replace {} with the name of the company responsible for the advancement in dryer screen technology.]

Upgrading Your Shaker Screens: Tips for Replacing and Choosing the Right Screens

Replacement Shaker Screens Transforming the Oil and Gas IndustryIn the ever-evolving oil and gas industry, technological advancements play a crucial role in optimizing efficiency and productivity. And one company at the forefront of this transformation is a leading innovator in the field of replacement shaker screens. By combining cutting-edge technology with a deep understanding of industry needs, this company is revolutionizing the way drilling fluids are filtered and processed.With global demand for oil and gas continuing to rise, drilling operations have become more complex and challenging. The extraction process involves drilling deep into the earth's crust, often in harsh and remote locations. Consequently, drilling contractors face numerous challenges in order to maintain profitable operations. Ensuring efficient solid control systems is a critical aspect of successful drilling, as it directly impacts the overall performance and longevity of drilling equipment.Replacement shaker screens are an integral component of a drilling rig's solid control system. They are used to filter out unwanted solids from drilling fluids, a process known as shale shaker. Shaker screens play a vital role in maintaining the quality and integrity of the drilling fluids, as well as protecting downstream equipment such as centrifuges and pumps. Hence, the durability, effectiveness, and efficiency of these screens are of utmost importance.The innovator in question has a long-standing reputation for producing high-quality replacement shaker screens that surpass industry standards. Their commitment to continuous research and development has led to breakthrough technologies that address the industry's most pressing challenges. By leveraging advanced engineering techniques, this company has created screens that excel in terms of durability, efficiency, and performance.One of the key features that sets these replacement shaker screens apart is the utilization of composite materials. By combining carefully selected grades of stainless steel with engineered polymer frames, these screens exhibit enhanced resistance to wear and corrosion. This ensures a longer lifespan, resulting in reduced maintenance costs and increased overall productivity.Moreover, the company's innovative screen design maximizes the usable screen area, significantly improving fluid handling capacity. This not only facilitates faster drilling operations but also minimizes the chance of screen blinding, a common issue faced by drilling contractors. With decreased screen blinding, operators are able to maintain optimal fluid flow rates, enhancing the overall efficiency of the drilling process.Furthermore, these replacement screens are meticulously engineered to deliver accurate particle separation. They employ advanced mesh technology that enables precise cut points, ensuring that only the desired solids are filtered out. This level of finesse in separation allows drilling contractors to better manage the drilling fluids' composition, thereby delivering superior drilling performance.The company's commitment to customer satisfaction extends beyond the quality of their products. They provide comprehensive technical support and responsive customer service, ensuring that their clients' specific needs are met. In an industry where downtime can have costly repercussions, this level of support is invaluable.To further enhance their service offering, the company actively collaborates with drilling contractors to develop customized solutions. By understanding the unique challenges faced by each client, they are able to tailor their screens to specific drilling conditions, thereby optimizing performance and efficiency. This collaborative approach has earned the company a loyal customer base and cemented their position as a trusted partner in the oil and gas industry.With replacement shaker screens playing such a vital role in the oil and gas sector, the technological advancements offered by this innovative company are poised to transform the industry. By improving durability, maximizing fluid handling capacity, enhancing particle separation accuracy, and providing exceptional customer support, they are revolutionizing the solid control process. As drilling operations continue to evolve, these replacement shaker screens serve as a testament to the power of innovation in shaping the future of the oil and gas industry.

Cutting-Edge Shale Shaker Technology: A Game-Changer in the Oil and Gas Industry

Title: Leading Industry Innovator Introduces Cutting-Edge Shale Shaker TechnologyIntroduction:In an era driven by rapid technological advancements, the oil and gas industry continues to seek innovative solutions that promote efficiency and improve extraction processes. One such breakthrough comes from a prominent industry player, renowned for its commitment to research and development. In this article, we explore the latest groundbreaking technology in shale shakers, introduced by this industry leader.Revolutionizing the Shale Shaker Market:Shale shakers play a pivotal role in the oil and gas industry by separating drilling cuttings from drilling fluids. This process is essential for maintaining the integrity of drilling fluids, enhancing operational efficiency, and minimizing potential environmental hazards. With these objectives in mind, the pioneering company, known for its dedication to excellence, has introduced an advanced shale shaker system that is set to transform industry standards.Unmatched Performance and Efficiency:The new shale shaker system demonstrates unparalleled performance and efficiency by incorporating cutting-edge technologies. By integrating state-of-the-art vibration control mechanisms, the shaker maximizes the separation of solids from drilling fluids, significantly reducing the environmental impact. This advanced technology minimizes waste, increases overall productivity, and ensures optimal fluid quality during drilling operations.The incorporation of intelligent sensors and data processing capabilities further enhances the efficiency of the shaker. Advanced algorithms accurately detect and analyze the characteristics and quality of the drilling fluid, allowing operators to make real-time adjustments to optimize performance. Additionally, the system's automated monitoring and control capabilities reduce operational risks, ensuring a seamless and safe drilling operation.Enhanced Durability and Cost Savings:Recognizing the need for superior durability in demanding drilling environments, this industry-leading company has engineered the shale shaker system with robust materials and craftsmanship. The shaker's structural integrity guarantees longevity, enabling continuous operation in the harshest conditions.Furthermore, the technological advancements in this shaker system result in substantial cost savings for operators. By effectively separating drilling cuttings and retrieving valuable drilling fluids, the system significantly reduces waste and maximizes resource utilization. This innovation leads to lower operational expenses and a noticeable positive impact on the bottom line.Safety and Environmental Considerations:The oil and gas industry is committed to maintaining high safety standards and minimizing environmental impacts associated with drilling activities. The new shale shaker system is designed with these priorities in mind. With advanced pressure relief mechanisms and automatic shutdown features, the system ensures operator safety while reducing the risk of equipment damage.Additionally, the ability to efficiently separate drilling cuttings from drilling fluids helps prevent contamination and promotes responsible waste management. Ensuring that drilling fluids are of the highest quality improves overall environmental stewardship while minimizing the impact on local ecosystems.Conclusion:In an ever-evolving industry, embracing cutting-edge technologies is key to ensuring efficiency, sustainability, and profitability. The introduction of the advanced shale shaker system by this industry-leading company heralds a new era of excellence in oil and gas operations.By combining unmatched performance, enhanced durability, and a strong focus on safety and environmental considerations, this revolutionary shale shaker system is poised to redefine industry standards. Operators can now benefit from increased efficiency, reduced operational costs, and enhanced environmental stewardship, solidifying their position as responsible industry leaders.As the oil and gas sector continues to push boundaries, it is innovations like these that pave the way for a sustainable and prosperous future.

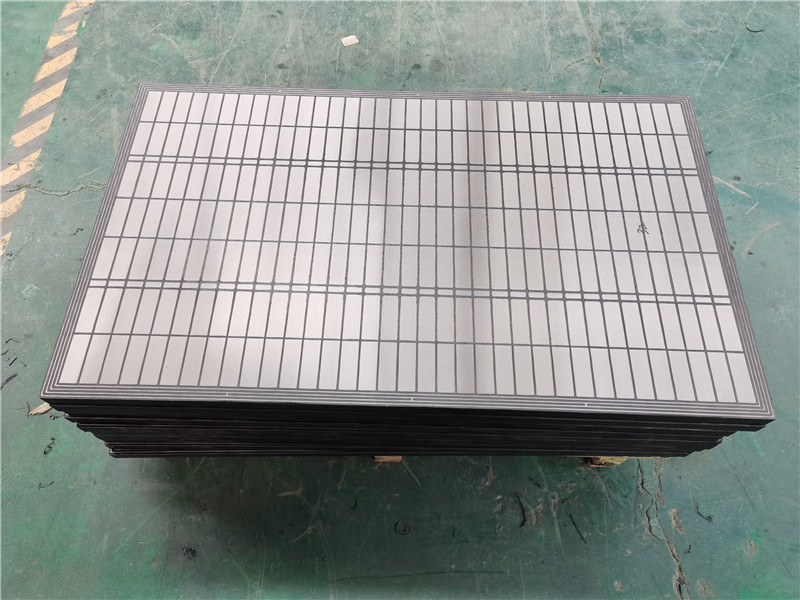

Steel Frame Shaker Screen with High Efficiency and Durability

Title: Cutting-Edge Steel Frame Shaker Screens Revolutionize the Oil and Gas IndustryIntroduction:In the fast-paced and demanding oil and gas industry, efficient drilling operations are crucial for maximizing productivity and profitability. One fundamental component of the drilling process is the shaker screen, which plays a critical role in separating drilling fluid from the drill cuttings. Recognizing the need for highly effective and durable shaker screens, {} has developed the groundbreaking GNZS-703 Steel Frame Shaker Screen. With exceptional efficiency and extended longevity, this game-changing technology is revolutionizing the way the industry operates.Part I: The Importance of Shaker Screens in Drilling Operations (150 words)To comprehend the significance of the GNZS-703 Steel Frame Shaker Screen, it is essential to understand the vital role shaker screens play in drilling operations. These screens act as the primary defense mechanism in the drilling process, separating undesirable solids from valuable drilling fluids. The efficiency and durability of shaker screens directly impact drilling operation costs, as ineffective screens lead to increased maintenance, decreased productivity, and elevated expenses. Thus, the development of advanced shaker screen technology holds immense potential in streamlining drilling operations.Part II: Introducing the GNZS-703 Steel Frame Shaker Screen (200 words)The GNZS-703 Steel Frame Shaker Screen is a cutting-edge innovation designed to optimize the performance and durability of shale shakers, improving overall drilling efficiency. Manufactured by {}, a renowned leader in oilfield equipment, this high-quality screen integrates innovative engineering, expert craftsmanship, and years of industry experience. The result is an exceptional product that surpasses industry standards in terms of efficiency, longevity, and cost-effectiveness.Constructed with precision-welded stainless steel wire mesh, the GNZS-703 Steel Frame Shaker Screen boasts excellent wear resistance, ensuring outstanding performance in the demanding drilling conditions. The frame is made from sturdy steel, providing robust structural support and extending service life. Additionally, the screen undergoes a specialized treatment process to enhance its corrosion resistance, enabling it to withstand harsh drilling fluids and adverse operating conditions.Part III: Key Advantages of the GNZS-703 Steel Frame Shaker Screen (250 words)The GNZS-703 Steel Frame Shaker Screen offers a multitude of advantages, making it a superior choice for drilling contractors and service providers. Firstly, its exceptional filtration efficiency guarantees the removal of a wide range of unwanted solids, preventing their reentry into the drilling fluid system. This not only enhances drilling fluid performance but also minimizes downtime related to fluid system maintenance.Moreover, the GNZS-703 Steel Frame Shaker Screen's long service life significantly reduces replacement costs, enhancing cost-effectiveness for drilling operations. The screen's heavy-duty construction ensures durability and reliability, enabling sustained performance even under heavy workloads. This translates into increased productivity and improved overall drilling efficiency.Furthermore, the upgraded design of the screen allows for easy installation and quick replacement, minimizing downtime and saving valuable operation hours. Its user-friendly nature simplifies maintenance, optimizing efficiency on-site.Conclusion (100 words)With the introduction of the GNZS-703 Steel Frame Shaker Screen, {} has raised the industry standard for shaker screen performance. By combining cutting-edge technology, superior materials, and expert engineering, this innovative product offers exceptional efficiency, extended service life, and substantial cost savings. The GNZS-703 Steel Frame Shaker Screen epitomizes the commitment of {} to providing the oil and gas industry with game-changing solutions that streamline drilling operations and increase profitability.

Latest Oil Shale Shaker Screen Delivers Optimal Performance and Efficiency

Oil Shale Shaker Screen Provides Enhanced Efficiency and Performance for Oil and Gas IndustryOil and gas exploration is a complex and demanding process that relies on a variety of advanced technologies to extract hydrocarbons from the earth's surface. One of the most critical components of the process is the oil shale shaker screen, which separates the rock and mud from the liquid oil in the drilling process. GNZS-752 Oil Shale Shaker Screen is a new product from one of the leading suppliers of oilfield equipment and services. The shale shaker screen delivers high-quality performance and increased efficiency in oil and gas exploration.The GNZS-752 Oil Shale Shaker Screen is a revolutionary product for the oil and gas industry. This product is designed to withstand the toughest and most challenging drilling conditions and improve drilling efficiency. The shale shaker screen is known for its ability to remove impurities from drilling liquids, making it ideal for oilfield applications. The screen is designed to filter out the solid waste material and allow only the fluid to pass through.The GNZS-752 Oil Shale Shaker Screen is designed to provide an exceptional user experience that is efficient, durable, and cost-effective. The screen is made from high-quality materials, including High Tensile Steel and Stainless Steel, and is constructed using advanced welding techniques, adding to its durability and overall quality. The GNZS-752 Oil Shale Shaker Screen comes with various mesh types to choose from, from coarse to fine mesh, providing flexibility and versatility for different drilling applications.Apart from the technical specifications of the product, the company's attention to detail in the manufacturing process is worth highlighting. The Company has a unique quality control system that ensures consistent performance and reliability of their products. Sophisticated testing equipment verifies all the products are of the highest quality. The Company uses state-of-the-art manufacturing processes to create products that not only meet but exceed industry standards and provide exceptional results to their customers.The GNZS-752 Oil Shale Shaker Screen is designed to be compatible with most drilling equipment used in the oil and gas industry, guaranteeing a smooth integration into the entire system. The product improves the efficiency of the drilling process, reducing costs and time for the oil and gas companies that use it. The shale shaker screen is environmentally friendly, and the reusable material makes it easier to comply with responsible waste management practices.The GNZS-752 Oil Shale Shaker Screen is ideal for various applications in conventional and unconventional drilling. The screen excels in removing large and small solids from the drilling fluids during the drilling process. The product is designed to be flexible, durable and maintain its effectiveness in high-pressure drilling environments where the drilling fluids cross the shaker screens on multiple occasions. The company behind the development, design, and production of the GNZS-752 Oil Shale Shaker Screen is a leader in the supply of oilfield equipment and services. The Company serves the international market and has a presence in several countries worldwide. The Company provides a variety of options, including mud cleaner, centrifugal pumps, mixing hoppers, and mud tanks, among others, that are essential in the oil and gas industry.The Company has a reputation for excellent customer service. Their customer service is standardized, providing customers with the same level of quality across all their worldwide locations. They offer their customers personalized service, providing detailed guidance on their products and materials. They also provide the necessary after-sales support through their dedicated and experienced technical support team.In conclusion, the GNZS-752 Oil Shale Shaker Screen provides the oil and gas industry with a reliable, efficient, and cost-effective solution. The screen is designed to enhance the drilling process and improve overall productivity, providing valuable benefits to oil and gas companies. The company's customer service, coupled with their technical support team, ensures that their clients receive the necessary information to make the best decision for their drilling operations. As the oil and gas industry continues to evolve, the GNZS-752 Oil Shale Shaker Screen is poised to play an even more critical role in helping companies to achieve their objectives with increased efficiency and profitability.